For any woodworking project, a table saw is an indispensable tool.

It is versatile, precise, and can make quick work of any cutting task.

There are several types of table saws available on the marke.

Each machine has its own unique features and capabilities.

With many types, it is really hard to find a suit one for your woodworking project.

However, it is not impossible.

In order to make an better decision, it’s necessary to understand the various types of table

saws on the market.

By familiarizing the different options, you can make the best choice for your

woodworking project.

There are many of type of table saw on market, but there are 6 type of table saw basiclly.

|

Saw

Type |

Pro |

Con |

|

Jobsite

Saws |

l Portable and

lightweight, l Easy to move around

job sites l Suitable for cutting

smaller materials l Affordable price

point |

l May not provide the

same level of precision and accuracy as other types l Limited capacity for

larger wood piece |

|

Contractor

Saw |

l Precise cutting l Versatile and affordable l Suitable for diy and

small workshop |

l Less powerful

compared to other types of saws l May not provide the

same level of precision and accuracy as other types l Limited capacity for large

wood piece l May require more

maintenance than other types |

|

Cabinet

Table Saw |

l Extremely powerful

and precise l Large cutting

capacity l Sturdy and durable

design, suitable for heavy-duty tasks l Safety and efficiency |

l Large and heavy l Higher price point l May require a

dedicated workspace due to its size l May consume more

power and require specialized wiring |

|

Hybrid

Table Saw |

l Equipped with

advanced features and accessories l Suitable for various

of cutting tasks l Provides a good balance

between affordability and performance l Versatile and

efficient |

l May not provide the

same level of power as a cabinet saw l Not as portable as a

contractor or foldable saw l May have a smaller

cutting capacity compared to a cabinet saw |

|

Sliding

Table Saw |

l Excellent precision

and accuracy, l Handle large and

thick wood board l Allows for

cross-cutting and angle cutting tasks |

l Large and heavy l Higher cost l Require a bigger

workspace l May consume more

power and require specialized wiring |

|

Foldable

Table Saw |

l Foldable and lightweight

l Easy to move around

job sites l Compact design allows

for easy storage and transportation l Suitable for cutting

smaller materials l Affordable price |

l May not provide the

same level of power and cutting capacity as other types l May have limitations

on the size of materials that can be cut l May not be as sturdy

and durable as other types l May require more

maintenance due to its compact design l Limited cutting

capacity |

Table of Contents

1. Jobsite Saws

A

Jobsite Saw, also known as a Portable Table Saw, Benchtop Saw or compact table

saw, is a type of table saw. It is designed to be lightweight, compact, and

easily transportable.

Compared

with stationary table saws, Jobsite Saws are easy and convenient to be moved

around from one job site to another.

It makes

job site saws an ideal option for people who need a reliable and portable

cutting tool.

Jobsite

Saws come in various sizes, but they’re generally smaller and more lightweight

than stationary table saws.

They are

designed with portability in mind, so they often feature a compact design with

folding legs or wheels for easy transportation.

Jobsite

Saws can handle a variety of cutting tasks, such as ripping, cross-cutting, and

beveling.

Many Jobsite

Saws also come with an adjustable fence and miter gauge, which allows for more

precise and accurate cuts.

Jobsite

Saw is less expensive than larger stationary table saws.

It is

about from $200-$1000. This makes them a popular choice for DIY enthusiasts who

want a reliable cutting tool without breaking the bank.

2. Contractor Saw

Contractor

saws are designed for use in a professional setting, such as a construction

site or workshop.

They are

larger and more powerful than jobsite saws, making them ideal for cutting

through thicker, tougher materials.

They

also offer more precision and accuracy than other types of saws, making them a

popular choice for woodworking enthusiasts and professionals alike.

Contractor

Saws are typically equipped with a powerful motor that can handle even the

toughest materials.

They

also have a larger table surface than other types of saws, which makes it

easier to cut larger pieces of wood.

Contractor

saws are equipped with a tilted blade.

It

allows you to make angled cuts, which can be incredibly useful for a variety of

woodworking projects.

Many

contractor saws also come with a rip fence, which helps ensure that your cuts

are precise and accurate.

Contractor

saws are more durable than other types of saws.

They are

typically made from high-quality materials that can withstand heavy use over

time. This makes them a popular choice for professional woodworking workers.

3. Cabinet Table Saw

Contractor

saws are designed for use in a professional setting, such as a construction

site or workshop.

They are

larger and more powerful than jobsite saws, making them ideal for cutting

through thicker, tougher materials.

They

also offer more precision and accuracy than other types of saws, making them a

popular choice for woodworking enthusiasts and professionals alike.

Contractor

Saws are typically equipped with a powerful motor that can handle even the

toughest materials.

They

also have a larger table surface than other types of saws, which makes it

easier to cut larger pieces of wood.

Contractor

saws are equipped with a tilted blade.

It

allows you to make angled cuts, which can be incredibly useful for a variety of

woodworking projects.

Many

contractor saws also come with a rip fence, which helps ensure that your cuts

are precise and accurate.

Contractor

saws are more durable than other types of saws.

They are

typically made from high-quality materials that can withstand heavy use over

time. This makes them a popular choice for professional woodworking workers.

4. Hybrid Table Saw

Hybrid

table saw is a popular type of table saw that combines the best features of a

cabinet saw and a contractor saw.

Hybrid

table saws have a smaller footprint than cabinet saws, making them ideal for

small workshops or homes.

Despite

its smaller size, it still can provide enough power to handle most woodworking

projects.

Hybrid

table saws were equipped with a fence system. It uses a T-square fence that

ensures accurate and precise cuts.

This

fence is easy to adjust and lock in place, which makes it a favorite among

woodworkers who demand accuracy and reliability.

A hybrid

table saw is an excellent choice for woodworking professionals who need a

powerful saw but do not have the space or budget for a full-sized cabinet saw.

5. Sliding or European Table Saw

A

sliding table saw is a versatile panel saw used to cut large sheets

of materials, such as plywood or MDF.

Sliding

table saws were equipped with a longer sliding table on a main body, which

allows it to cut material with precision and accuracy.

Compared

to traditional table saws, the sliding table saw has a few advantages.

For one,

it allows the user to cut larger sheets of material without additional support

or extension tables.

Additionally,

the sliding table ensures that the workpiece is always in contact with the

blade, which can result in more accurate cuts.

It’s

very useful when cutting large or thick pieces of wood piece.

Sliding

table saws will be larger and heavier than traditional table saws, which can

make them difficult to move around a workshop or job site.

Additionally,

the sliding carriage can take up the amount of space, which may be a concern

for users with limited workspace.

Sliding

table saws ‘cost range from $ 5000 to $ 20000.

It can

be more expensive than traditional table saws due to their complexity.

However,

for those who work with larger wood sheets or require precise cuts, it may be

worth it.

In

conclusion, a sliding table saw can be a valuable addition to any woodworking

shop or job site.

While

they may be larger and more expensive, it’s worth buying for a professional

woodworker or medium-sized factory.

6. Integrated Foldable Table Saw

Foldable table saw, a portable table saw, is more and more popular in the woodwork

industry.

Foldable table saws is a built-in stand that can be folded for easy storage and

transportation.

It is perfect for those who have limited space in their workshop or need to transport

their saw to job sites.

The folding stand makes it easy to pack up the saw and take it with you wherever

you go.

Foldable table saws can be used for a wide range of woodworking projects, from cutting

large wood sheets to precisely cutting smaller pieces.

The foldable stand also makes it easy to adjust the height of the saw to match the

height of your workbench, which can be a real-time-saver.

It is equipped with sturdy frames and powerful motors that can handle

even the toughest cutting jobs.

They are also designed to be easy to maintain, with simple blade-changing mechanisms and easy-to-clean surfaces.

If you’re looking for a versatile, durable, and easy-to-use table saw that is also

easy to transport and store, an integrated foldable table saw may be the right

choice for you.

7. What Are The Cut Types On A Table Saw?

Table saws can allow for precision cuts that would be difficult to achieve with other tools. There are several cut types on a table saw, and each has its unique application.

Let’s dive into the different types of cuts and what they are used

for.

● Rip Cut

Rip Cut involves cutting a piece of wood along its length, usually parallel to the

grain.

A rip cut can be made using the saw’s rip fence as a guide, ensuring a straight and

accurate cut.

Rip cuts are often used to create narrow strips of wood or to reduce the width of a board.

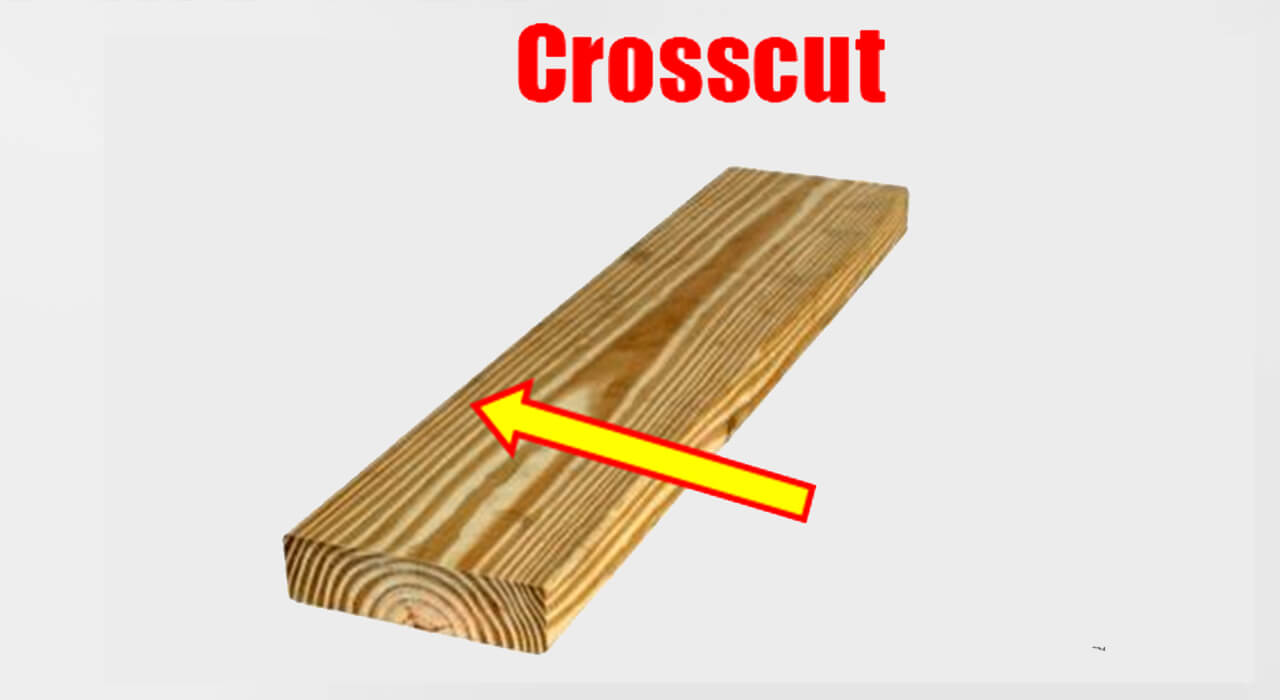

● Crosscut

Unlike the rip cut, the crosscut involves cutting a piece of wood across its width,

usually perpendicular to the grain.

Crosscuts are made using a miter gauge or a crosscut sled, which keeps the wood steady as

it’s fed through the saw blade.

Crosscuts are ideal for cutting pieces to length or for creating angled cuts.

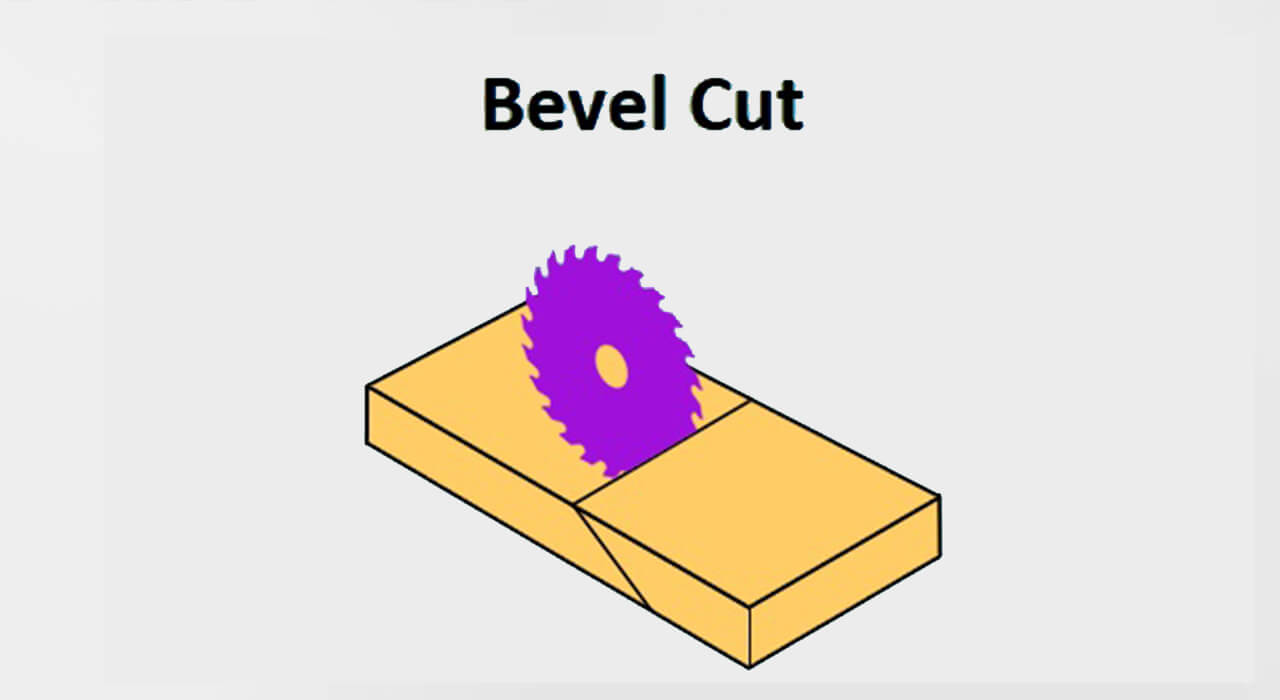

● Bevel Cut

Bevel

cuts are made by tilting the saw blade to an angle other than 90 degrees.

This

type of cut is often used to create angled edges on a piece of wood.

Bevel

cuts can be made in two ways: by tilting the blade and using a rip fence, or by

tilting the blade and using a miter gauge or crosscut sled.

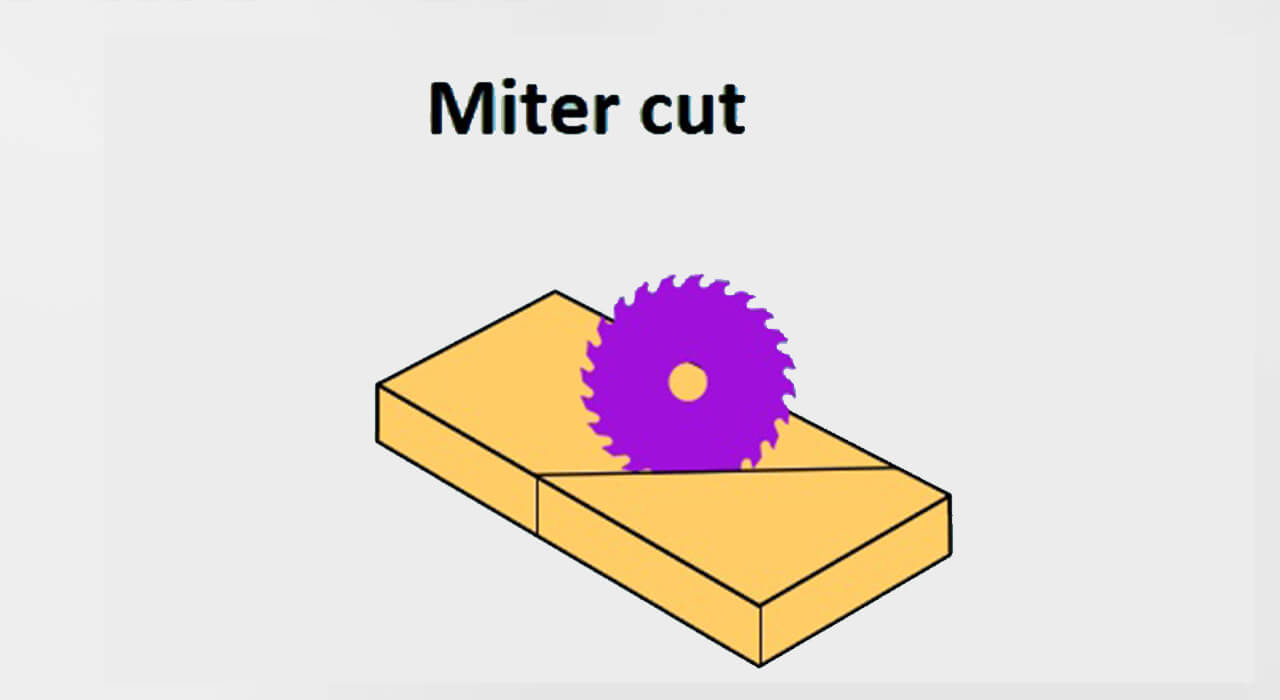

● Miter Cut

Miter cut is an angled cut made on the end of a piece of wood, commonly at 45

degrees, allowing for tight joints and perfect corners.

Miter cuts are commonly used in a variety of woodworking projects such as picture

frames, moldings, and door frames.

With the help of a table saw and a miter gauge, creating precise and tight corners has

become much easier.

In conclusion, a miter cut is a critical technique in woodworking, and using a

table saw with a miter gauge is the best way to achieve a perfect cut.

● Dado Cut

A dado cut involves removing a groove or channel from a piece of wood.

This type is often used in cabinetry and furniture making to create joints and slots

for shelves and other components.

Dado cuts are made by adjusting the saw blade height and using a specialized dado

blade set, which consists of two outer blades and a set of chippers that remove

the wood between them.

In conclusion, whether you’re making rip cuts, crosscuts, bevel cuts, compound

cuts, or dado cuts, it’s essential to use the appropriate safety equipment and

follow the manufacturer’s instructions to ensure a safe and accurate cut.

So, before starting any project, make sure you have the right tools.

8. What Saw Is Best For Ripping Plywood?

When it

comes to cutting plywood, a sliding table saw is the best tool for the job.

The

sliding table saw is specifically designed to make precise and accurate cuts,

which is essential when working with plywood.

Unlike

other saws, the sliding table saw has a sliding table that moves back and forth,

allowing you to cut large pieces of plywood with ease.

When

cutting plywood, a sliding table saw ensures a clean and accurate cut.

The

sliding table reduces the risk of kickback and prevents the blade from

wandering.

It means

you don’t worry about the saw-wandering off.

If you’re looking to rip plywood, a sliding table saw is the way to go.

It can

cut large plywood boards precisely and accurately.

So, if

you’re serious about woodworking, you can invest in a sliding table saw.

9. How To Maintain Woodworking Machine?

When it

comes to cutting plywood, a sliding table saw is the best tool for the job.

The

sliding table saw is specifically designed to make precise and accurate cuts,

which is essential when working with plywood.

Unlike

other saws, the sliding table saw has a sliding table that moves back and forth,

allowing you to cut large pieces of plywood with ease.

When

cutting plywood, a sliding table saw ensures a clean and accurate cut.

The

sliding table reduces the risk of kickback and prevents the blade from

wandering.

It means

you don’t worry about the saw-wandering off.

If you’re looking to rip plywood, a sliding table saw is the way to go.

It can

cut large plywood boards precisely and accurately.

So, if

you’re serious about woodworking, you can invest in a sliding table saw.

10. What Saw Is Best For Cutting Straight Lines?

If you cut right angles with precision, the best type of saw to use is a miter saw.

A miter saw is designed to make precise angled cuts, making it perfect for creating

perfect 90-degree angles.

The saw’s blade is mounted on a pivot, allowing it to move in a controlled manner

and cut at precise angles.

You can create perfect 90-degree cuts every time, without the need for additional

measuring or marking.

Additionally, this saw can make angled cuts in both directions, making it ideal for creating

intricate designs and shapes.

In conclusion, when it comes to cutting right angles, a miter saw is the best saw to us.

11. To Sum Up

Classifying

table saws can be a challenging task, as the boundaries between different types

of saws are often blurry.

However,

I have strived to provide a comprehensive overview of the various types of

table saws in the market.

By now,

you must have noticed the similarities and differences between each of them.

Now that

you are equipped with this knowledge, it’s time to find the perfect table saw

that suits your specific needs.

Whether

you’re looking for a hybrid saw, cabinet saw, or contractor saw, there are

plenty of options to choose from.

So go

ahead, start your search for the ideal saw, and take the first step towards

creating remarkable woodworking projects!