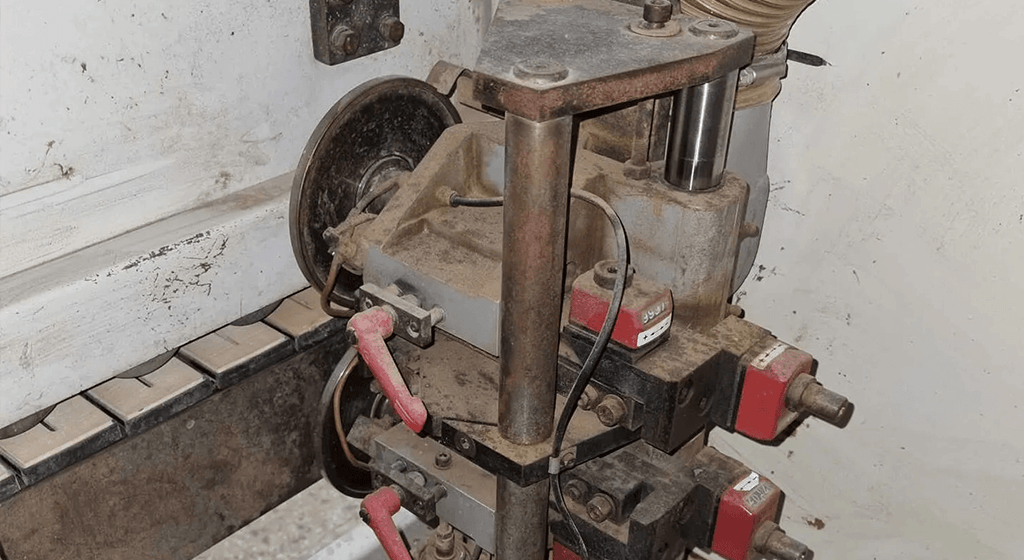

An Edge Banding Machine is an important machine in woodworking shops.

If you neglect routine care, it can lead to costly repairs and downtime, affecting production efficiency.

Hence, it is essential to implement a thorough maintenance regime to ensure the machine’s longevity and consistent high-quality results.

Table of Contents

1. Daily Maintenance

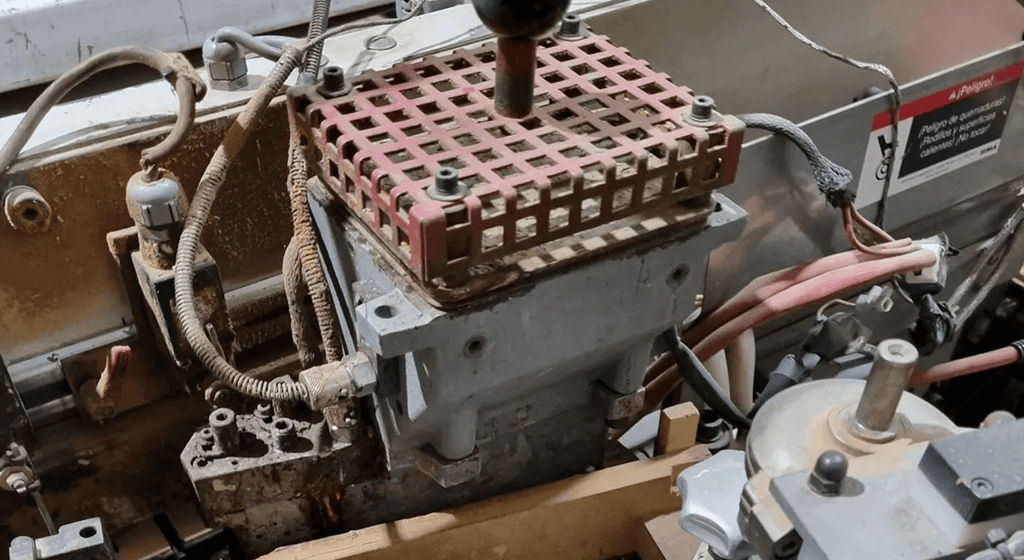

1.1. Cleaning the Glue Pot

Cleaning the Glue Pot should be a daily task. This prevents glue buildup, which can hinder adhesion quality.

A clean glue pot also reduces the risk of clogs, ensuring a smooth and consistent glue flow.

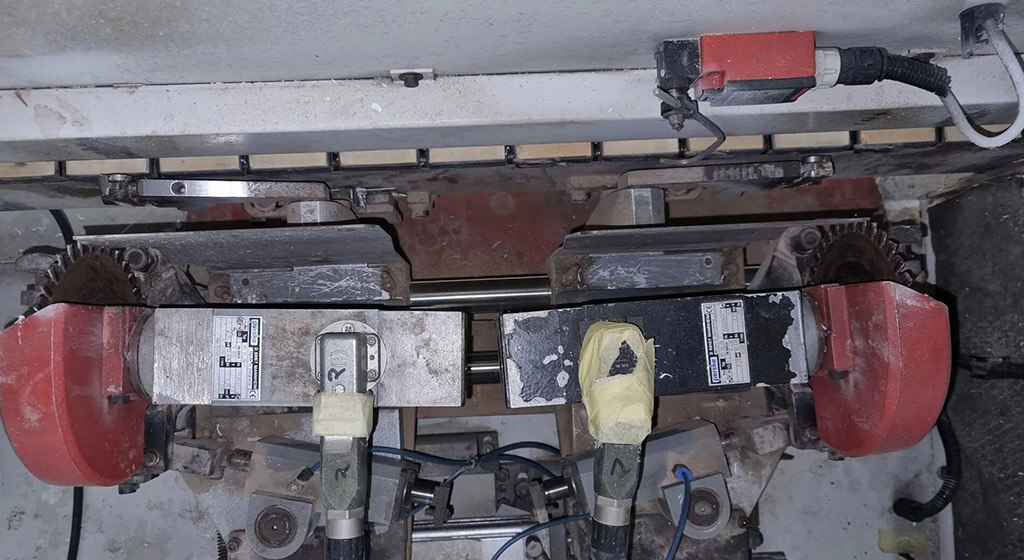

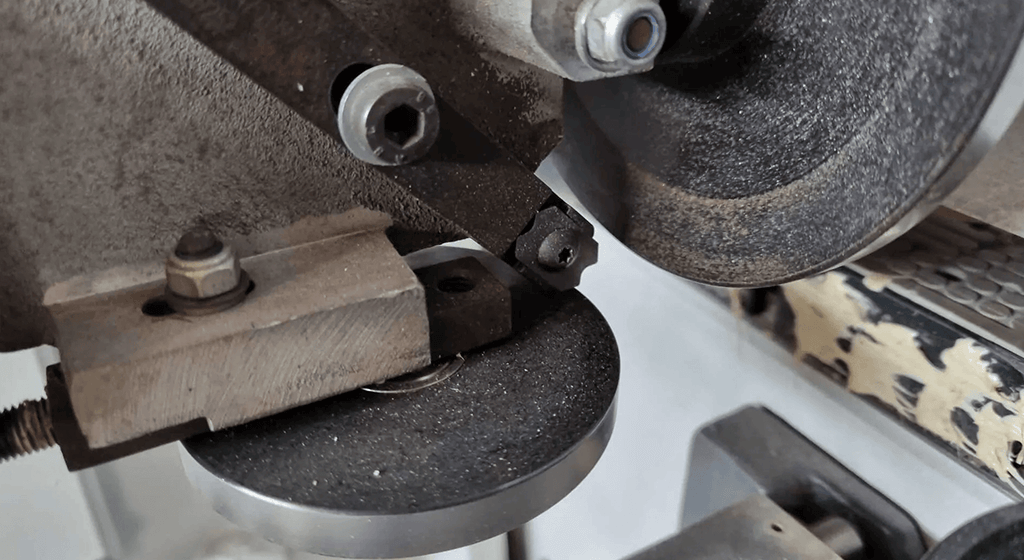

1.2. Inspecting Trimming Blades and Cutters

Regularly inspecting trimming blades is crucial. Dull edges can ruin your finished product.

Sharp blades are essential for achieving clean, precise cuts that enhance the overall appearance of your work.

1.3. Removing Dust and Debris

Dust and debris can accumulate quickly, especially in busy production environments.

Regularly cleaning the machine’s exterior prevents unnecessary wear and ensures all parts function efficiently.

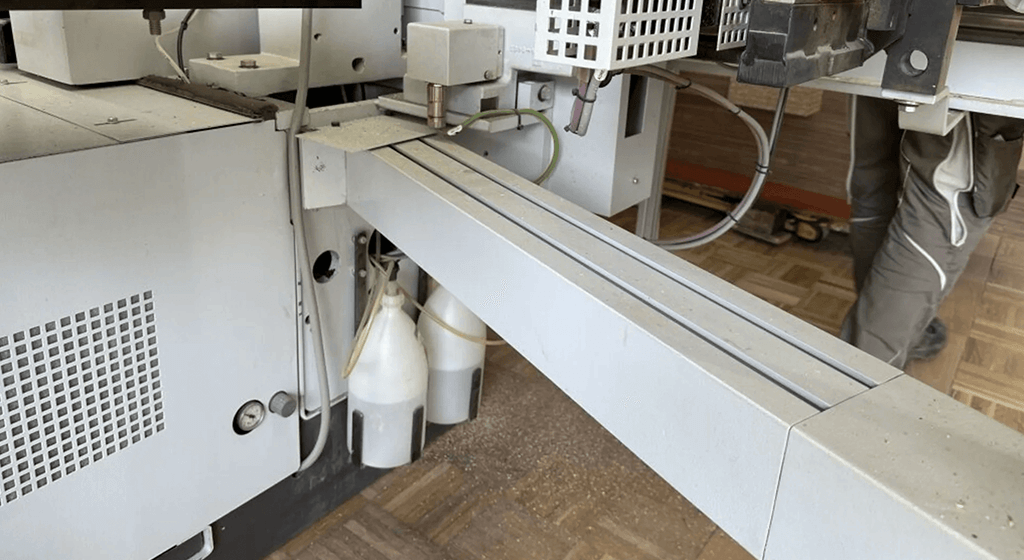

1.4. Checking the Conveyor Belt for Wear

Daily checks on the conveyor belt are necessary. Look for signs of wear or damage. A worn belt can cause slippage or misalignment, leading to uneven banding.

Proper maintenance keeps materials moving smoothly through the machine.

1.5. Lubricating Moving Parts

Lubrication is key for moving parts like gears and rollers. Weekly lubrication reduces friction and prevents premature wear. This maintenance step helps ensure smooth operation and increases the machine’s longevity.

1.6. Inspecting Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems are vital to an edge-banding machine’s operation.

Regular inspections ensure pressure levels are optimal and identify any leaks or malfunctions, keeping your machine running smoothly.

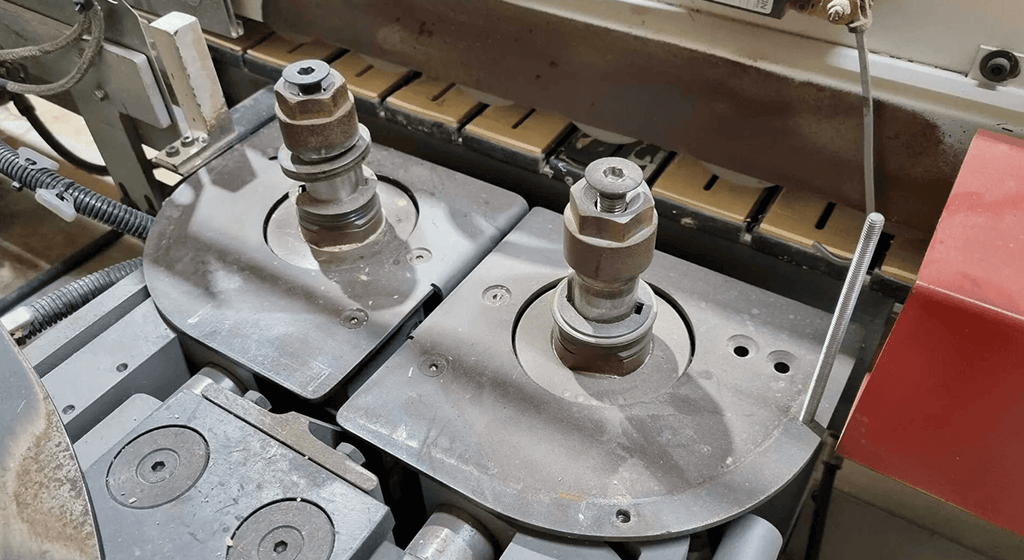

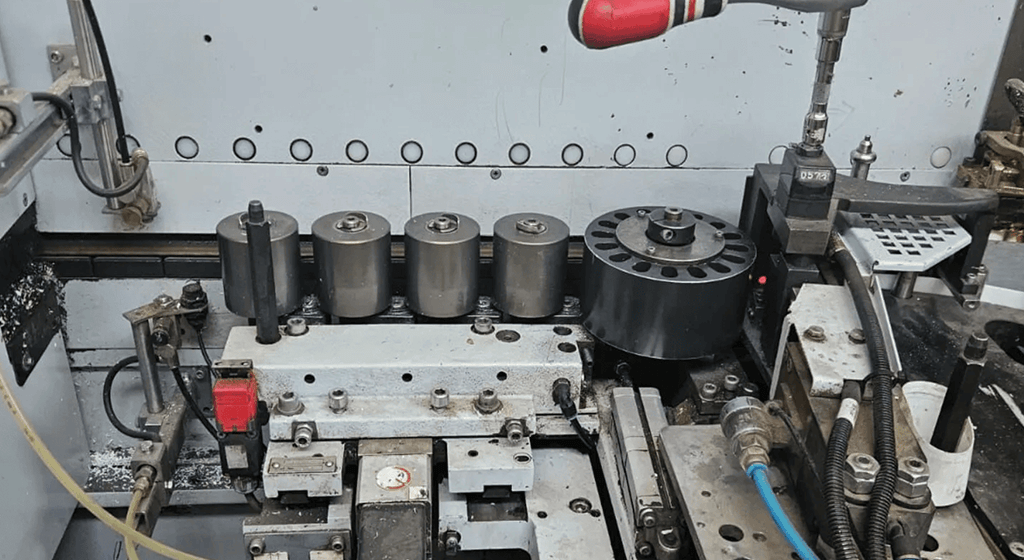

1.7. Checking the Alignment of the Pre-Milling Unit

Pre-milling units must be aligned correctly for accurate edge preparation. Misalignment can lead to poor adhesion and uneven finishes.

Regular alignment checks should be part of your weekly maintenance routine.

1.8. Ensuring Proper Function of Edge Scrapers

Edge Scrapers need to be in excellent condition. Dull or misaligned scrapers can leave imperfections on finished edges.

Maintaining scrapers is critical for achieving high-quality results.

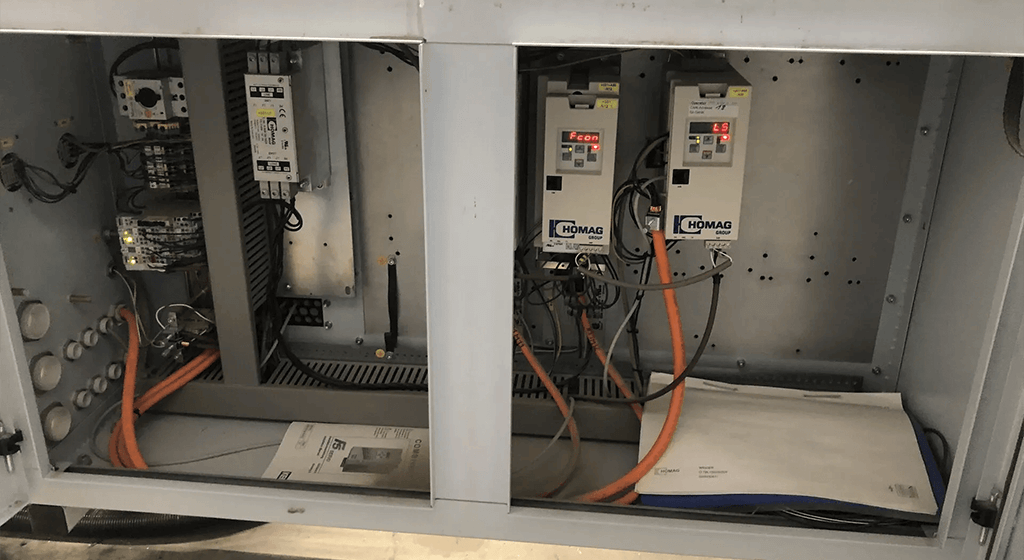

1.9. Examining Electrical Connections

Loose or damaged electrical connections can lead to performance issues.

Monthly checks of all electrical components help ensure stable and reliable machine operation.

1.10. Monitoring the Pressure Zones for Accuracy

Pressure zones play a vital role in even banding application. Regular monitoring of these zones maintains the correct pressure for different materials, ensuring consistent results.

1.11. Calibrating Control Systems

Control systems must be calibrated regularly. Proper calibration ensures accurate machine settings.

This precision is essential for everything from glue application to trimming operations.

1.12. Inspecting Buffing and Sanding Units

Buffing and sanding units require routine checks. Worn components can lead to inconsistent finishes.

Replacing worn pads and belts is crucial for maintaining quality output.

2. Deep Cleaning and Seasonal Maintenance

2.1. Removing Residual Glue Buildup

2.2. Replacing Worn-out Blades and Buffing Pads

2.3. Deep Inspection of Glue Rollers and Feed Mechanism

2.4. Checking for Signs of Rust or Corrosion

3. Troubleshooting Common Issues

3.1. Glue Application Inconsistencies

Inconsistent glue application can lead to weak bonds. Regularly inspecting the glue system and maintaining proper temperature control can help resolve these issues.

3.2. Misaligned Edges or Uneven Finishes

3.3. Reduced Efficiency in Trimming and Scraping

3.4. Conveyor Belt Slippage

4. Preventing Common Issues

4.1. Recognizing Signs of Glue Contamination

4.2. Avoiding Edge Banding Material Jams

4.3. Ensuring Consistent Edge Feed

5. Key Areas for Periodic Inspection

5.1. Pre-Milling Unit Blades and Alignment

5.2. Edge Banding Feeder System

5.3. Calibrating Buffing Units

6. Troubleshooting Common Problems

6.1. Glue Pot Malfunctions: Identifying Solutions

6.2. Addressing Edge Inconsistencies

6.3. Dealing with Incomplete Trims

7. Best Practices for Long-Term Maintenance

7.1. Using Quality Edge Banding Materials

7.2. Scheduling Professional Maintenance Checks

7.3. Keeping Spare Parts Readily Available

Having spare parts on hand reduces downtime during repairs. Essential parts include blades and glue nozzles, ensuring you’re prepared for any issues.

8. Summing Up

By following these maintenance guidelines, you can enhance the performance and longevity of your edge-banding machine, ensuring high-quality results in all your woodworking projects.