Cabinet Making Machines

Process

Cabinet Making Machine.

Are you searching for reliable, high-performance cabinet making machines to elevate your woodworking business?

BESTIN, a trusted woodworking machine manufacturer, provides top-tier solutions for cabinet production, ensuring speed, precision, and quality at every stage.

Whether you need a CNC cabinet-making machine, sliding table saw, or edge banding machine, our advanced technology is designed to meet all your cabinet production needs.

What Machines Do Cabinet Makers Use?

Cabinet makers typically use a variety of specialized machines, including:

- CNC Cabinet Making Machine for precision cutting and shaping.

- Sliding Table Saw for panel cutting.

- Edge Banding Machine for seamless edge finishes.

- Hinge Boring and Multi-Boring Machine for assembly drilling.

Our Best-Selling Cabinet Making Machines

CNC Cabinet Making Machines

Our CNC machines ensure precision cutting, drilling, and shaping for cabinets of any size and design.

- Advanced CNC cabinet making software integration.

- Optimized for MDF, plywood, and other cabinet materials

- Easy-to-use interface for maximum efficiency.

- Custom configurations available.

Sliding Table Saws

Our sliding table saws provide smooth, accurate cuts ideal for cabinet parts and panels.

- Heavy-duty structure for durability

- Precision guides for error-free operation

- Compact designs for small workshops

Automatic Edge Banding Machines

Perfectly finish cabinet edges with precision and durability using our edge banding machines.

- Seamless, durable edge finishes for MDF and wood veneers.

- Compact designs with optional 10” TFT LCD touch screens.

- High-speed performance for increased productivity.

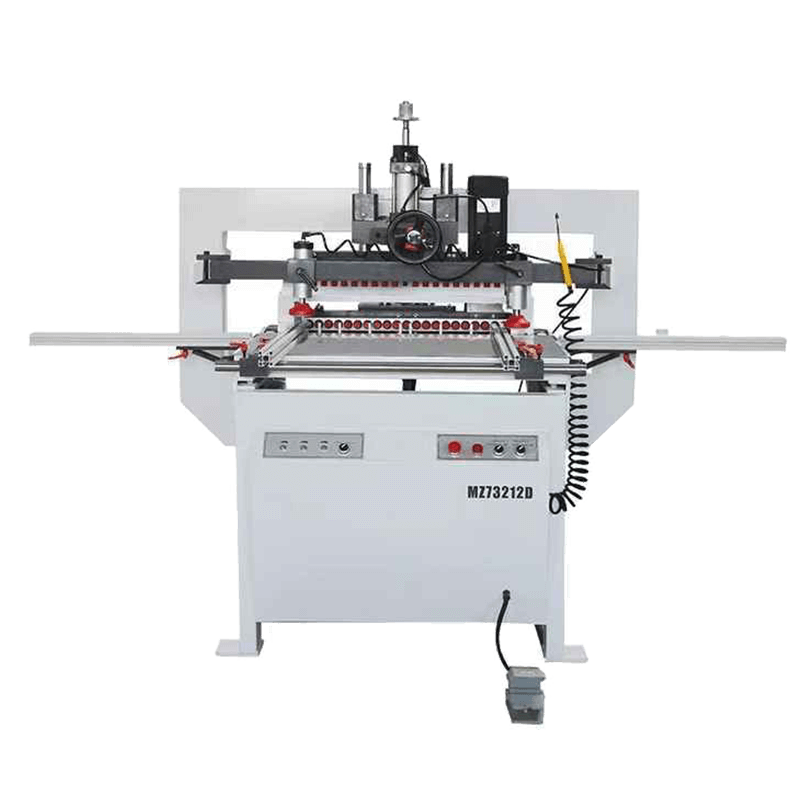

Multi-Boring & Hinge Boring Machines

Streamline cabinet assembly with precision drilling for hinges, dowels, and connectors.

- Automated boring for efficient production.

- Multiple spindle options for flexibility.

- Easy adjustment for various drilling patterns.

Why Choose BESTIN for Cabinet Making Machines?

At BESTIN, we combine cutting-edge engineering with customer-focused service to deliver state-of-the-art woodworking machines. Our CNC cabinet making machines streamline production, improve accuracy, and reduce manual labor—empowering you to produce cabinets faster and more profitably.

Key Benefits:

- High Precision: Achieve flawless cuts, edges, and finishes every time.

- Time-Saving Solutions: Advanced automation for reduced production time.

- Cost-Effective: Competitive pricing without compromising quality.

- Customizable Options: Tailored machines to meet your specific requirements.

- Global Support: Fast, reliable customer service and shipping worldwide.

Affordable Solutions

At BESTIN, we offer competitive CNC cabinet machine prices without sacrificing quality. Contact us today to receive a customized quote tailored to your business needs.

FAQ About Cabinet Making Machines

What Is The Cabinet Making Machine

A cabinet making machine is a specialized woodworking machine used for the design, cutting, shaping, and assembly of cabinets and other wood furniture. These machines are essential for achieving precision and efficiency in cabinet production.

What Machines Are Used in Cabinet Making?

Cabinet makers use various machines to streamline their workflow:

- CNC cabinet making machines for precision cutting and shaping.

- Sliding table saws for accurate panel cutting.

- Edge banding machines for finishing cabinet edges.

- Hinge boring machinery for drilling accurate holes for cabinet hinges.

- Multi-boring machines for efficient drilling of multiple holes simultaneously.

What Is a CNC Machine Used for in Cabinet Making?

A CNC machine for cabinet making is used to automate the cutting, drilling, and shaping of wood materials like MDF and plywood. These machines ensure high precision and speed, reducing manual labor and material waste.

How Does a CNC Machine Help in Cabinet Making?

A CNC cabinet machine streamlines the production of cabinets by automating tasks like:

- Cutting panels to size with precision.

- Drilling holes for hinges and fittings.

- Shaping cabinet parts with high accuracy.

- Reducing human error and production time.

Can CNC Machines Cut Wood and MDF?

Yes, CNC machines are designed to cut wood, MDF (Medium Density Fiberboard), plywood, and other types of wood materials commonly used in cabinet making. These machines offer smooth and precise cuts, making them ideal for cabinet production.

What is the Best CNC Machine for Cabinet Making?

The best CNC machine for cabinet making depends on your specific needs, such as the type of materials you work with, production volume, and desired features. Machines with high precision, customizable features, and user-friendly software integration, such as BESTIN CNC cabinet making machines, are ideal for both small and large-scale cabinet shops.

How Much Does a CNC Cabinet Making Machine Cost?

The price of a CNC cabinet machine varies based on factors such as the machine’s features, size, and customizations. On average, CNC machines for cabinet making range from a few thousand to tens of thousands of dollars. Contact BESTIN for a tailored quote based on your requirements.

Can CNC Machines Make Furniture?

Yes, CNC machines can be used to make a wide variety of furniture, including cabinets, tables, chairs, and more. These machines offer high precision and are particularly effective for complex, custom furniture designs.

What is Edge Banding in Cabinet Making?

Edge banding is a process used to apply a thin strip of material (such as wood veneer or PVC) to the edges of cabinet panels. This process improves the appearance and durability of the edges, providing a clean, seamless finish.

Can CNC Machines Cut Other Materials Besides Wood?

While CNC machines are primarily used for wood, they can also cut other materials such as plastics, composites, and light metals, depending on the configuration and tools used.

What Is MDF Used For in Cabinet Making?

MDF (Medium Density Fiberboard) is a popular material used in cabinet making due to its smooth surface, versatility, and affordability. It is often used for cabinet doors, shelves, and drawer components.