CNC Beam Saw

CNC Beam Saw

- Unmatched Cutting Accuracy

- Increased Throughput

- Reduced Material Waste

- Versatile Panel Handling

- Flexible Automation

CNC Beam Saw NP280B

The BESTIN CNC Beam Saw NP280B is an industrial‑strength panel cutting solution engineered for precision, productivity, and long-term reliability.

Designed with a heavy‑duty welded steel frame and five‑axis CNC‑machined mounting surfaces, the NP280B delivers straight, smooth cuts every time.

Whether you’re processing large furniture panels or delicate veneers, this automatic panel saw optimizes cycle times and minimizes waste, making it the perfect choice for medium‑ to high‑volume woodworking workshops.

Benefits

Unmatched Cutting Accuracy

The massive, heat‑treated steel frame and precision‑machined guide rails guarantee ±0.1 mm cutting precision, so every panel cut is square and true.-

Increased Throughput

A 2 kW servo‑driven saw carriage coupled with fast travel speeds (up to 80 m/min cutting, 100 m/min return) means more cuts per hour—boosting your shop’s productivity. -

Reduced Material Waste

The dual scoring saw (1.5 kW) and automatic cut‑height projection improve edge quality on delicate laminates, minimizing chipping and costly rework. -

Versatile Panel Handling

Hydraulic rear lift, air‑cushioned bed, and heavy‑duty steel return conveyors handle panels from 8 mm thin veneers up to 100 mm thick boards with ease.

-

Flexible Automation

Choose single or twin pusher operation via the PC‑based “PreCut” optimization software to match your production flow—ideal for batch or mixed‑panel workflows.

Picture

Features

- Heavy-Duty Construction

The NP280B features a CAD-designed welded steel frame, tempered to eliminate internal stresses and precision-machined on a five-axial CNC. This ensures maximum stability, accuracy, and longevity, even under heavy loads. The massive frame guarantees consistent precision, making it a reliable choice for high-volume production.

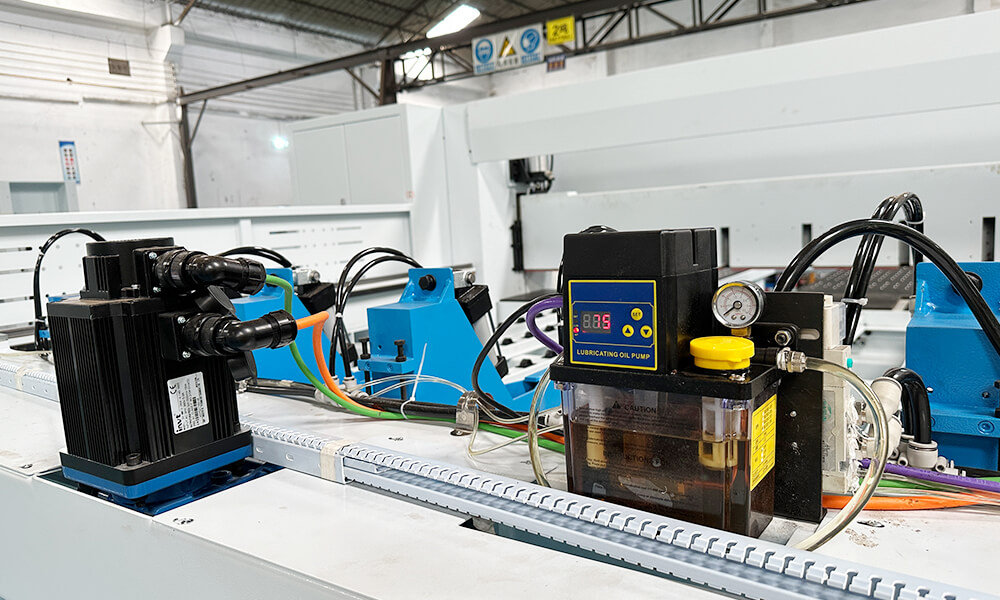

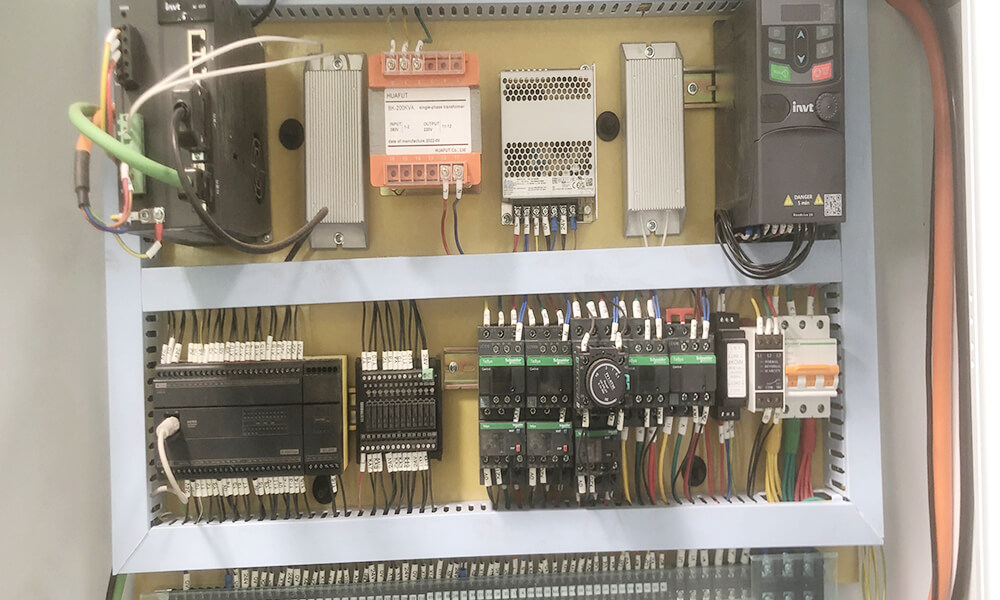

- Advanced CNC Control System

Equipped with a Windows-based Industrial PC controller, the NP280B offers an intuitive interface with graphic displays for each cutting stage. The PRECUT Optimizing Software enhances productivity by:

- Automatically calculating cutting plans.

- Managing remnants to reduce waste.

- Enabling label printing with flexible formatting.

- Supporting the import of cut lists from Excel for seamless integration.

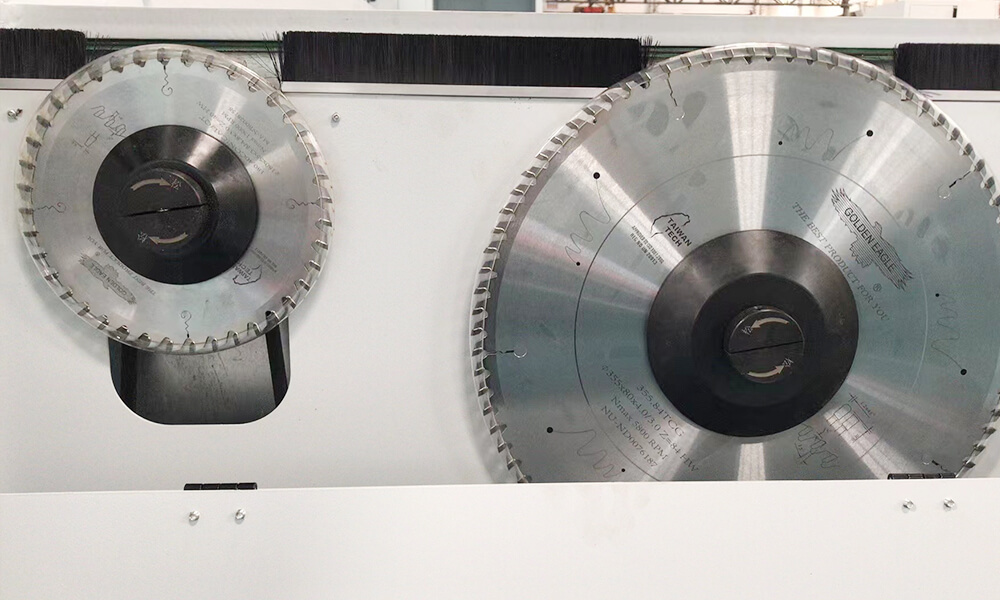

- Powerful Cutting Capabilities

The NP280B is powered by an 18.5kW main saw and a 1.5kW scoring saw, delivering precise, high-quality cuts across various materials, including plywood, MDF, and particleboard. The quick blade change system minimizes downtime, while automatic cut height projection ensures consistent cut quality, reducing errors and improving output.

- Hydraulic Rear Lift

A steel cable-driven rear lift table supports panels as thin as 8mm, providing flexibility for diverse material thicknesses. This feature optimizes panel positioning, streamlining the loading process and enhancing workflow efficiency.

- Optimized Saw Travel

A 2kW servomotor drives the saw carriage, ensuring fast and accurate movements. The heat-treated precision rack and large diameter pinion drive gear guarantee smooth, reliable operation, minimizing wear and maintaining performance over time.

- Air-Cushioned Bed and Tables

The air cushion system prevents scratching of sensitive panels, preserving material quality. Four repositionable air-cushioned worktables accommodate various panel sizes, offering flexibility for different project requirements.

- Safety and Reliability

Safety is prioritized with a 1.8-meter high safety fence featuring interlocking access doors. The NP280B uses CE-compliant electrics and electronics, ensuring safe and dependable operation in any professional setting.

- Pneumatic Clamping

The industry-leading two-finger clamping structure uses air cylinders to securely hold panels without damaging surfaces. This ensures cutting accuracy, even for delicate materials, by preventing movement during operation.

- Roller Conveyor

A roller conveyor system assists panel movement, protecting surfaces from scratches and making it easier to handle heavy panels, further enhancing operational efficiency.

Technical Data

|

Max Cutting Width (Horizontal) |

2750mm |

|

Small Saw Motor Power |

2.2kw |

|

Max Cutting Thickness |

100mm |

|

Scoring Saw Blade Outer Diameter |

Φ180mm |

|

Max Cutting Length (Vertical) |

2600mm |

|

Secondary Saw Blade Inner Diameter |

Φ55mm |

|

Targeting |

Automatic |

|

Secondary Saw Speed |

6100r/Min |

|

Servo Positioning Accuracy (Precision

Square Rail) |

2.0kw(0.02mm) |

|

Sawing Speed |

0-80m/Minute |

|

Sawing Precision |

±0.1mm |

|

Return Speed |

100m/Minute |

|

Main Saw Motor Power |

15kw(Optional 18.5kw) |

|

Air Pressure |

0.6-0.8mpa |

|

Main Blade Outer Diameter |

Φ350-400mm |

|

Total Installed Power |

24kw/(Optional 28kw) |

|

Main Saw Blade Inner Diameter |

Φ80mm |

|

Front Loading Air Bearing Power |

4kw |

|

Main Saw Speed |

4100r/Min |

|

Weight |

4800kg |

|

Traction Servo Power (Rack Drive) |

2.0kw(Servo Optional) |

|

Machine Size (L X W X H) |

5300×5950×1900mm |

Video&Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com