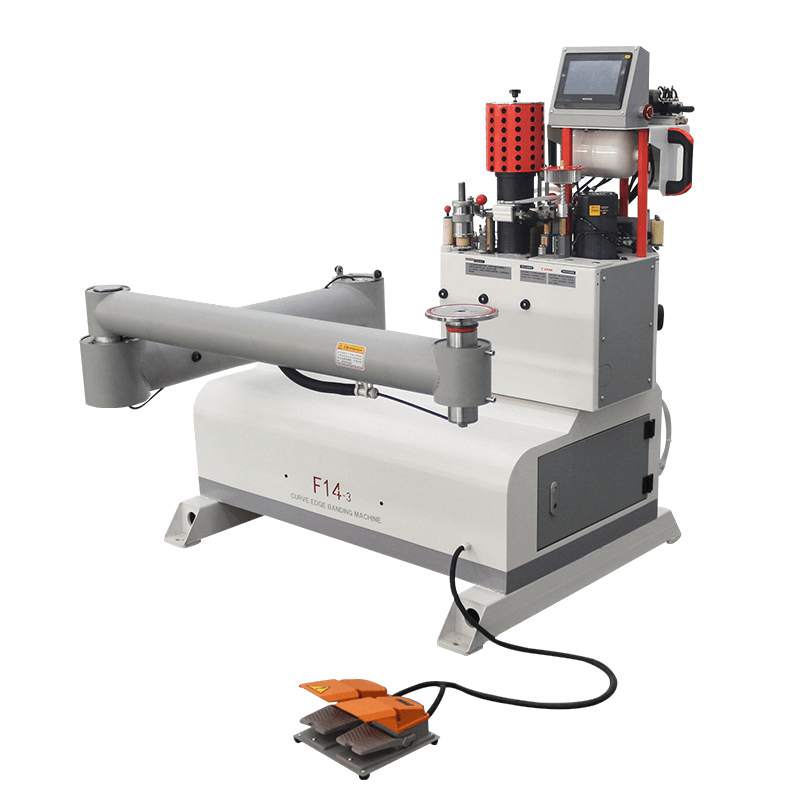

Automatic Curved Edge Banding Machine

Automatic Curved Edge Banding Machine

- Ideal for Curved Shapes

- Combined Banding and Trimming

- Automatic Feeding for Curves

- Dual Glue Options with Easy Discharge

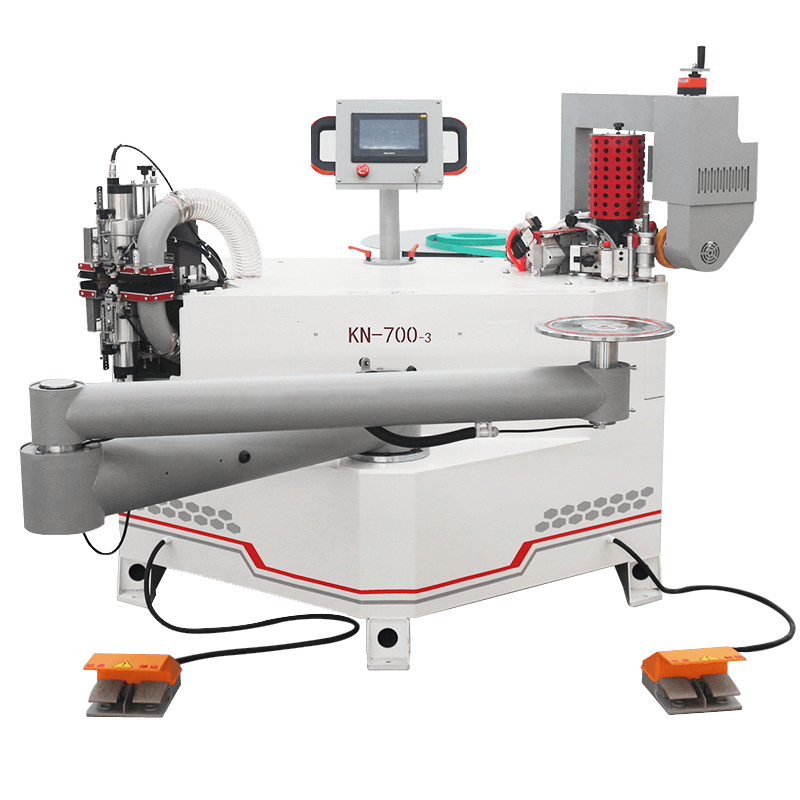

Automatic Curved Edge Banding Machine-700-3

Upgrade your woodworking game with our Automatic Curved Edge Banding Machine – a versatile solution designed for precision and efficiency. Comprising an edge banding unit and a trimming unit, this machine is tailor-made for curved wood boards.

Benefits

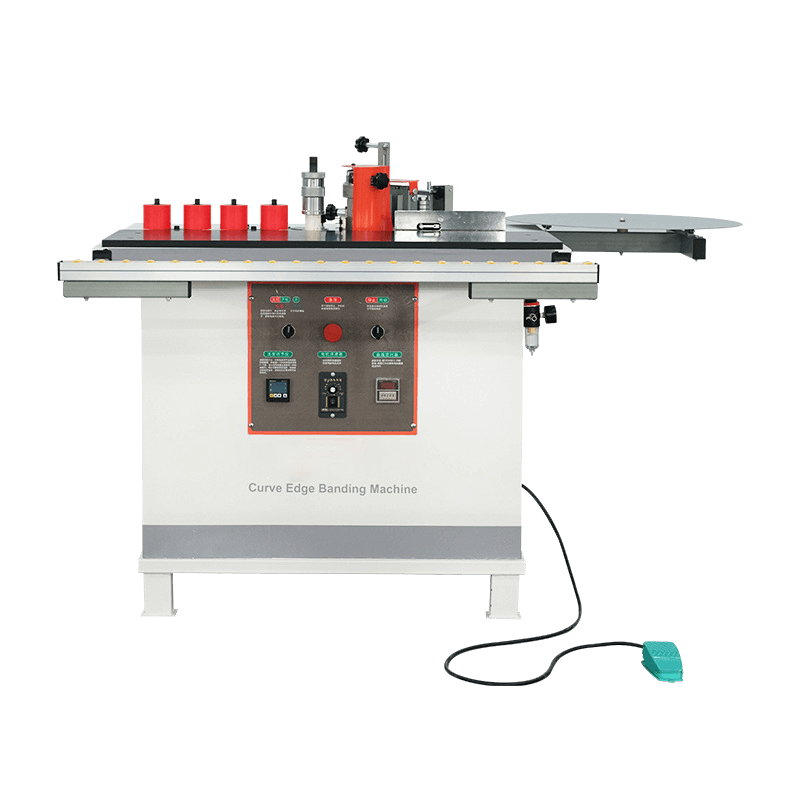

- Ideal for Curved Shapes

Especially suitable for round, oval, and rounded rectangle shapes, providing versatility in your woodworking projects.

- Rotatable LCD

The LCD is rotatable for easy operation, ensuring a user-friendly experience.

- Advanced Gluing System

Our automatic curved edge banding machine is equipped with an upper glue pot, boasting a 2600ml capacity. It supports both PUR and EVA, featuring an insulation function that shortens heating time. One-click

glue discharge facilitates easy glue change.

- Higher Machine Head

An upgraded machine head allows the selection of wider sealing strips, providing flexibility in your projects.

- Combined Banding and Trimming

This automatic curved edge banding machine seamlessly combines edge banding and trimming in one, simplifying operations, especially for larger boards.

Picture

Features

- Automatic Feeding for Curves

Ideal for round, oval, and rounded rectangle boards, the machine offers automatic feeding for efficient processing.

- Laser Ranging for Precision

The laser ranging feature ensures precise docking with an error of ±0.3mm, eliminating the need for manual cut strip adjustments.

- Dual Glue Options with Easy Discharge

The machine supports both PUR and EVA glues, with a convenient one-click discharge feature for quick and hassle-free glue changes.

- Servo Motor for Stability

Featuring a servo motor for fast action response and low noise, the machine ensures stability during operations.

- High-Speed Feeding

With a feeding speed ranging from 0 to 30cm/s, the machine delivers high work efficiency for your projects.

- Efficient Cleaning Mechanism

The machine comes equipped with four automatic cleaning devices that spray cleaning liquid. Adjustable spray and intermittent times enhance the cleaning process.

- Expanded Glue Pot Capacity

The glue pot now holds 2600ml, reducing the need for frequent glue additions. The heat preservation function minimizes waiting time for heating with just one click.

- Intuitive Touch Screen

The touch screen can store 20 kinds of sheet data, streamlining the use of sheet data and significantly improving work efficiency.

- Pressure-Retaining Air Storage Tank

The adoption of a 2L pressure-retaining air storage tank ensures the normal operation of pneumatic components in unstable external air pressure conditions.

- Enhanced Bonding with Heating Device

A single heating device enhances the bonding between strips and the board, ensuring a firm connection.

- User-Friendly Foot Switches

Both the edge banding unit and the trimming unit come with foot switches, offering a simple and convenient operational experience.

Technical Data

|

Voltage |

380V/50Hz/3Phase |

|

Air Pressure |

0.6-0.8Mpa |

|

Glue Pot Temperature |

110-210°C |

Head Rotation Angle |

15° |

|

|

Trimming Speed |

0-24cm/s |

Diameter of External Dust Collector |

150mm |

|

|

Total Power |

6.5kW |

Glue Pot Capacity |

2600ml |

|

|

Type of Hot Melt Adhesives |

EVA/PUR |

Edge Strip Width |

14-70mm |

|

|

Edge Strip Thickness |

0.5-3mm |

Boards Thickness for Trimming |

<14mm single-sided trimming; 14-70mm

double-sided trimming |

|

|

Inner Arc Radius |

≥20mm |

Gas Tank Volume |

2L |

|

|

Banding Speed |

0-30cm/s |

Applicable Edge Strip Material |

PVC/Plastic/Melamine/Veneer (need to be

customized) |

|

|

Packing Dimension |

1870*1400*1530 (L*W*H mm) |

Packing Weight |

530kg |

Video&Brochures

We Are Here For You!

- +1 (310) 571-7396

- Info@bestingroup.com

- www.bestingroup.com