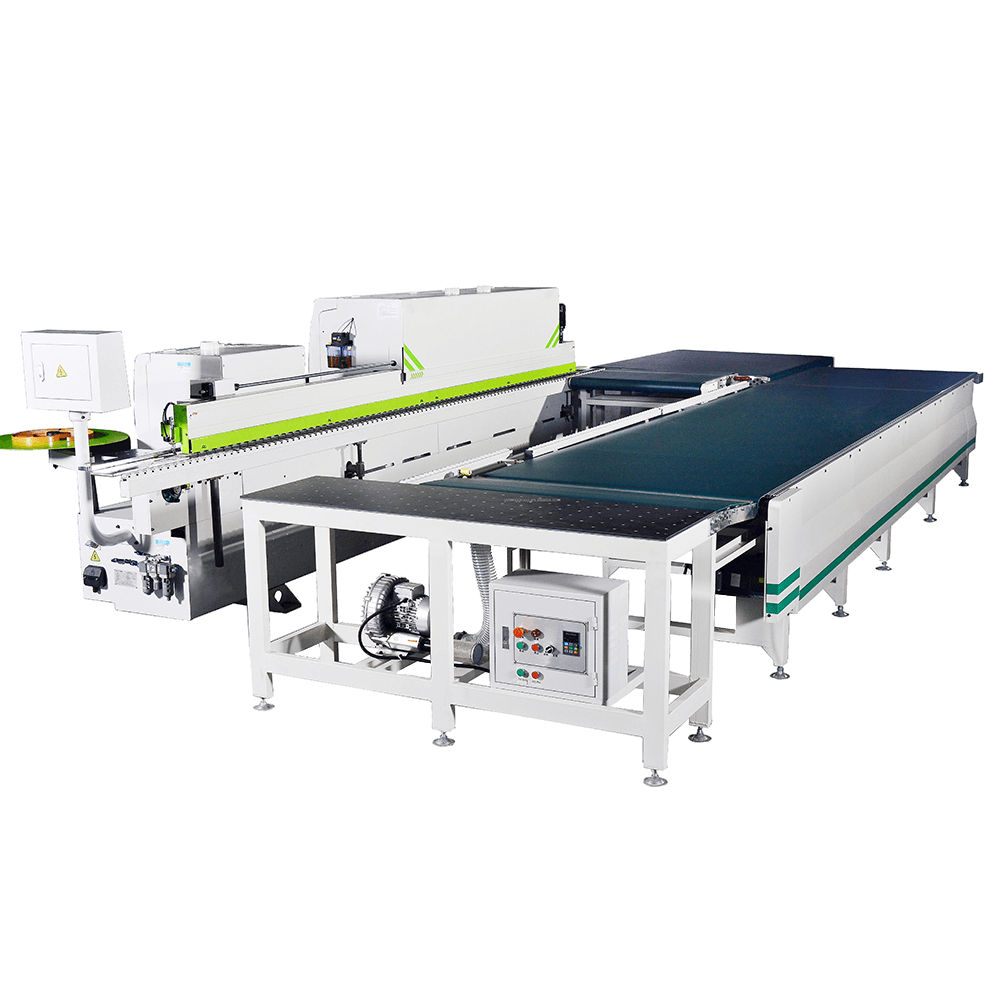

Automatic Edge Banding Machine

Automatic Edge Banding Machine.

BESTIN’s automatic edge banding machine is built for craftsmanship and efficiency. Designed for woodworkers and companies, it offers a simple, flexible solution for precise edge processing.

Whether aiming to speed up production or enhance product quality, BESTIN’s edge bander is the perfect choice to elevate your woodworking projects.

Automatic Edgebander

BestIn automatic edge banding machine delivers flawless edge finishes on materials like PVC, ABS, and wood veneer.

- Fast, Automatic Operation: Save time with automatic feeders and pre-milling for smooth, precise edges.

- Strong, Seamless Joints: Our advanced gluing systems (PUR and EVA) ensure a perfect bond every time.

- Professional Finish: Achieve clean, durable edges with trimming, milling, scraping, and buffing units.

- Easy To Operate

- High-performance Machines

- Excellent Flexibility

- Maximum Automation

Edge Banding Machine For Sale

Our extensive range of automatic edge banding machines is tailored to suit your needs. In addition to providing top-quality machines, we also offer OEM and ODM services that can help grow your brand and enhance your woodworking machine business

Item No. | BE486TK |

Panel Thickness | 10-60mm |

Edge Band Thickness | 0.4-3mm |

Panel Width | ≥80mm |

Panel Length | ≥150mm |

Feeding Speed | 20-26m/min |

Working Pressure | 0.6mpa |

Voltage | 380v,50hz/60hz |

Total Power | 30.03kw |

Item No. | BE486G |

Panel Thickness | 10-60mm |

Edge Band Thickness | 0.4-3mm |

Panel Width | ≥80mm |

Panel Length | ≥160mm |

Feeding Speed | 12-20m/min |

Working Pressure | 0.6mpa |

Voltage | 380v,50hz, 3phase |

Total Power | 10.52kw |

Item No. | BE365YG |

Panel Thickness | 10-60mm |

Edge Band Thickness | 0.4-3mm |

Panel Width | ≥80mm |

Panel Length | ≥160mm |

Feeding Speed | 12-20m/min |

Working Pressure | 0.6mpa |

Voltage | 380v,50hz, 3phase |

Total Power | 6.51kw |

Item No. | BE486YG |

Panel Thickness | 10-60mm |

Edge Band Thickness | 0.4-3mm |

Panel Width | ≥80mm |

Panel Length | ≥160mm |

Feeding Speed | 12-20m/min |

Working Pressure | 0.6mpa |

Voltage | 380v,50hz, 3phase |

Total Power | 16.3kw |

Item No. | BE365T |

Panel Thickness | 10-60mm |

Edge Band Thickness | 0.4-3mm |

Panel Width | ≥80mm |

Panel Length | ≥160mm |

Feeding Speed | 12-20m/min |

Working Pressure | 0.6mpa |

Voltage | 380v,50hz, 3phase |

Total Power | 9.6kw |

Automatic Edge Banding Machine Feature

Sturdy Base

The heavy-weight structure makes the machine run steadily.

Automatic

The automatic handling feature maximizes production capability and saves human costs.

Advanced Glue Unit

Advanced glue systems always make a flawless edge appearance.

Easy Operation

The "Quick-Set-System" enables you to make rapid adjustments to different materials.

Highlights

Our machine applies edge banding evenly and accurately with six rollers.

The specialized glue-spreading roller maintains a consistent temperature, ensuring a uniform application of glue, even at maximum panel heights.

Our optional rapid unlocking mechanism for the glue pot allows for quick changes and flexibility in your workflow.

Our machine supports EVA or PUR to meet your needs.

Our machine features an advanced end-trimming unit for perfect edge finishing.

With two high-frequency motors, it ensures precision and lasting performance.

The trimming unit glides along prismatic guideways fitted with preloaded recirculating ball bearings, providing smooth and accurate cutting.

The end saws are securely mounted on a robust cast base, utilizing high-precision THK guides for flawless alignment.

It allows you to achieve impeccable edge trimming for all your woodworking projects.

After gluing, our machine effectively trims excess edge banding on the front and rear of the panels.

It can accommodate various edge types, ensuring every cut is clean and precise.

Our machine features a cutting-edge trimming unit powered by two high-frequency motors. This ensures precise and consistent trimming results every time.

Our machine includes a vertical copying device with a large rotating disc, ideal for handling hinge holes effortlessly.

It is equipped with dual rotating bearings, providing superior accuracy for all your projects. Each copying disk has finely ground contact surfaces, guaranteeing high precision in every cut.

To boost productivity, the machine is also equipped with a rapid-release mechanism for both electrical and mechanical motors, allowing for quick adjustments and seamless operation.

It features a robust round scraper unit designed for superior performance. Mounted securely on a sturdy column, this unit ensures a vibration-free operation for a smooth finish every time.

Perfect for finishing 2 mm PVC and ABS edges, the scraper effectively removes excess glue from the panel edge, resulting in a clean and professional look.

With the ability to change blades easily, this unit efficiently trims thin chips from plastic edges, eliminating cutter marks and glue residue.

BESTIN automatic edge banding machine features a powerful buffing unit that ensures your edges shine.

Equipped with two high-performance motors, this unit cleans and polishes edges to perfection, giving your panel work a flawless finish.

Designed for efficiency, the buffing unit enhances the cleaning process, effectively removing any imperfections from the applied edges.

It works seamlessly with various materials, using specialized buffing wheels like Molto fins and Scotch Brite for outstanding results.

Pre-milling Unit (Optional).

Our machine features an advanced pre-milling unit that prepares your panel edges before gluing. With two high-frequency motors, this unit precisely trims edges for a smooth, uniform surface.

Our pre-milling unit effectively eliminates these imperfections, ensuring optimal edge quality.

It operates with two spindles: the first gently mills away a thin layer, while the second cuts the edge flat for seamless gluing.

This advanced technology guarantees professional results, enhancing both durability and appearance.

Choose BESTIN for exceptional edge banding performance.

Corner Rounding Unit (Optional).

BESTIN’s automatic edge banding machine have an advanced corner rounding unit.

This unit is equipped with a high-frequency motor and precise copying devices that ensure top-quality results.

After edge banding, workpiece corners can be sharp. Our corner rounding unit smooths these edges quickly and accurately.

With high-precision guideways and recirculating ball bearings, the unit glides seamlessly for efficient operation.

Images

Edge Banding Type

Our automatic edge banding machine is designed to produce both flat and knife edge banding with precision and ease. Trust us to provide you with the perfect solution for all your edge banding needs.

Flat Edge Banding

Knife Edge Banding

Edge Banding Sample

Bestin’s automatic edge banding machine delivers flawless precision and efficiency.

The machine’s high-frequency motors and smart copying technology guarantee sharp, precise edge rounding, giving your projects a professional look.

The pre-milling unit prepares the surface by trimming uneven edges, while the zero-joint technology eliminates visible glue lines.

It ensures that your furniture work looks modern, sleek, and high-end.

With BESTIN’s innovative technology, you can achieve consistent, professional results in less time, boosting productivity and ensuring that each project meets the highest standards.

Automatic Edge Banding Machine Application

Bestin’s automatic edge banding machines are perfect for woodworking tasks like applying edge materials to furniture panels and cabinet doors. These machines work with a wide range of edge banding materials, including PVC, ABS, veneer, and solid wood. They offer precise application, ensuring a seamless and consistent finish on every panel edge.

Kitchen Cabinets

Bestin’s automatic edge banding machines are perfect for producing seamless edges on kitchen cabinet doors and drawers. These machines can handle a variety of edge banding materials. They ensure custom-designed cabinets match any style or taste, creating durable, high-quality edges that enhance the overall look of kitchen furniture.

Furniture Panels

Bestin’s automatic edge banding machines give furniture panels a clean, finished look by precisely applying edge banding materials. Ideal for custom designs, they deliver smooth edges, making your furniture pieces stand out with a flawless, professional finish.

Office Furniture

Bestin’s automatic edge banding machines are perfect for crafting office furniture like desks, filing cabinets, and bookshelves. These machines apply edge banding to create smooth, professional edges, giving your office furniture a clean and polished finish. Perfect for manufacturers looking for efficiency and precision.

Doors And Windows

Bestin’s automatic edge banding machines are ideal for creating professional, finished edges on doors and windows. It not only enhances the appearance, but also adds long-lasting protection to the edges of doors and window panels, preventing wear over time.

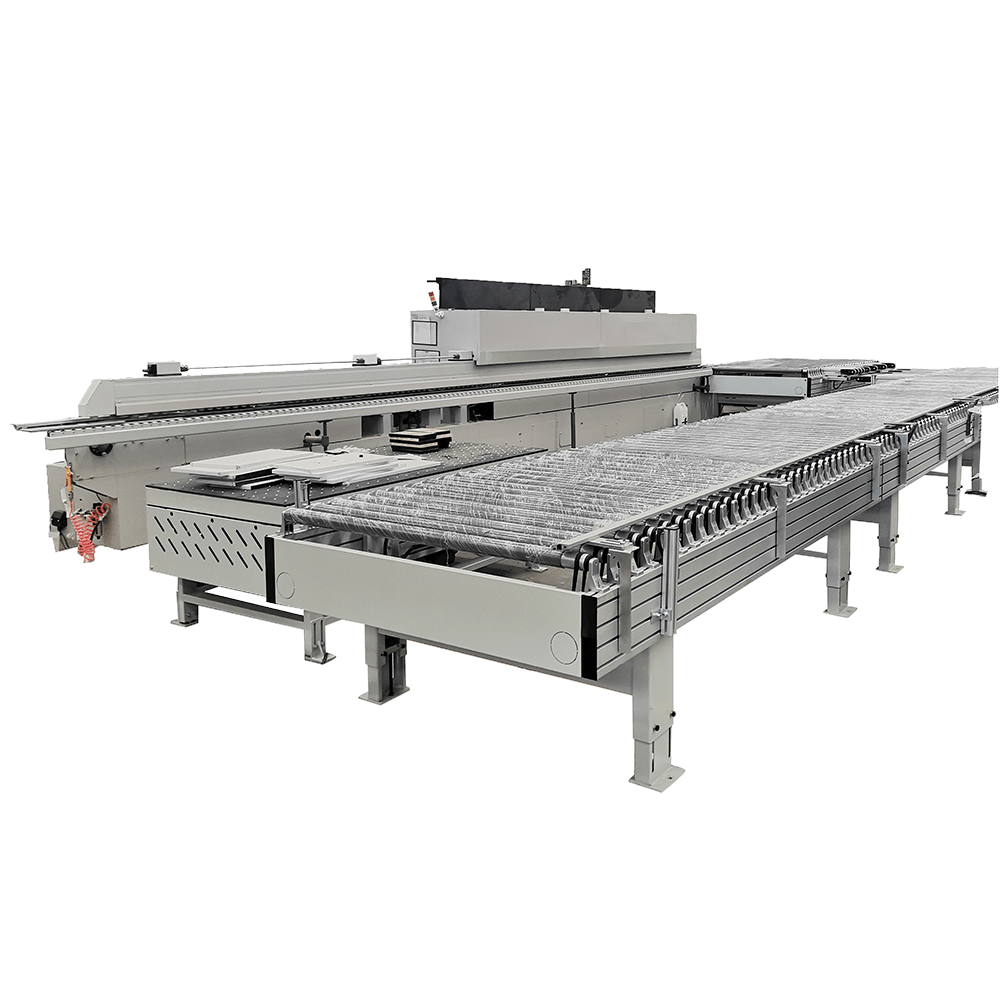

Return Conveyors

At Bestin, we understand that efficient production is key in woodworking. Our return conveyors are the perfect complement to edge banding machines, enhancing your entire edging process.

These systems create a smooth, automated flow of materials, boosting efficiency in furniture production.

Feature

- Optimized Workflow: Our return conveyors streamline the flow of workpieces, making your edging process leaner and more organized. Whether you handle custom orders or mass production, our systems adapt to your needs.

- Automated Efficiency: Even entry-level edge banding machines become powerful with our return conveyors. One operator can manage the entire process, reducing labor costs and improving productivity. Say goodbye to manual feeding and embrace automation.

- Flexible and High-Performance: Our conveyors ensure continuous performance for high-volume furniture production. With features like barcode identification, parts are efficiently turned, transferred, and ejected, keeping your operation running smoothly.

- Protective Handling: We prioritize the safety of your materials. Our conveyors utilize air cushion tables and vacuum systems to protect sensitive surfaces, from lightweight panels to heavy components. Your products will always be handled with care.

- Ergonomic Design: Our systems enhance operator comfort. With features like lifting tables, you can eliminate the strain of manual handling. This means better morale and less fatigue for your team.

Key Benefits

- Improved Machine Utilization: Maximize the capabilities of your edge banding machines.

- Reduced Downtime: Keep your production running without interruptions.

- Versatile Applications: Handle a wide range of workpieces with ease.

- High Profitability: Experience quick returns on your investment.

- Simple Operation: Easy to use, even for new operators.

Investing

in a Bestin return conveyor is not just a choice; it’s

a step toward greater efficiency. Upgrade your edge banding operation today and

enjoy the benefits of streamlined automation. Discover the perfect solution for

your woodworking needs with BESTIN.

Why Choose BestIn

At Bestin, we are committed to producing high-quality automatic edge banding machines using only the best components. Our core parts are sourced from SGS and CE-certified manufacturers, ensuring they meet rigorous quality and performance standards. It guarantees our machines deliver reliable performance and precise results, making them the perfect choice for professionals who demand excellence.

Affordable Solutions

Elevate your woodworking production with the Bestin Automatic Edge Banding Machine.

Contact us today to learn more about how our machine can enhance your operations.

FAQ About Automatic Edge Banding Machines

What is an Automatic Edge Banding Machine?

An Automatic Edge Banding Machine is a specialized piece of equipment used in woodworking to apply edge banding materials—such as PVC, ABS, or melamine—to the edges of panels.

This process enhances the aesthetic appeal and durability of furniture components by providing a seamless and professional finish.

How does the Bestin Automatic Edge Banding Machine work?

The Bestin Automatic Edge Banding Machine operates through a series of automated steps:

- Pre-Milling: The machine pre-mills the edges of the panels to ensure a smooth surface for the edge banding.

- Gluing: It applies a uniform layer of adhesive to the panel edges.

- Edge Banding: The machine feeds the edge banding material onto the glued edges, ensuring a secure bond.

- Trimming: Excess edge banding is trimmed from the panel’s front and rear ends.

- Fine Trimming: The machine refines the edge banding to align perfectly with the panel’s surface.

- Scraping and Polishing: It scrapes and polishes the edges to achieve a smooth and glossy finish.

This automated process ensures consistency, efficiency, and high-quality results in edge banding applications.

What materials can the Bestin Automatic Edge Banding Machine handle?

The Bestin Automatic Edge Banding Machine is versatile and can handle various edge banding materials, including:

- PVC

- ABS

- Melamine

- Wood Veneer

- Acrylic

This flexibility allows manufacturers to produce a wide range of products with different aesthetic and functional requirements.

What are the key features of the Bestin Automatic Edge Banding Machine?

The Bestin Automatic Edge Banding Machine offers several notable features:

- High-Speed Operation: Achieves feeding speeds up to 26 meters per minute, enhancing production efficiency.

- Dual Quick-Melt Glue Pots: Ensures a consistent and strong bond by maintaining optimal adhesive temperature.

- Advanced Trimming Devices: Equipped with four high-speed round contouring trimming devices for precise and rapid corner trimming.

- User-Friendly Interface: Features a PC Auto-counter interface for intuitive operation and monitoring.

- Automatic Lubrication System: Automatically lubricates guide rails on the end trimming unit, ensuring smooth operation and extending machine lifespan.

What are the applications of the Bestin Automatic Edge Banding Machine?

The Bestin Automatic Edge Banding Machine is ideal for various applications, including:

- Furniture Manufacturing: Producing cabinets, tables, and chairs with seamless edges.

- Interior Design: Creating custom panels and decorative elements with professional finishes.

- Woodworking Workshops: Enhancing productivity and product quality in workshops.

Its versatility makes it a valuable asset in any woodworking production environment.

What is the price range of the Bestin Automatic Edge Banding Machine?

What is the warranty period for the Bestin Automatic Edge Banding Machine?

The Bestin Automatic Edge Banding Machine comes with a standard one-year warranty, covering manufacturing defects and ensuring peace of mind. Extended warranty options are available upon request.

How can I maintain the Bestin Automatic Edge Banding Machine?

Regular maintenance is essential to ensure optimal performance:

- Daily Cleaning: Remove adhesive residues and dust after each use.

- Lubrication: Utilize the automatic lubrication system to maintain moving parts.

- Inspection: Regularly check for wear and tear on components.

Can the Bestin Automatic Edge Banding Machine be customized?

Yes, the Bestin Automatic Edge Banding Machine can be customized to meet specific production requirements.

Customization options include modifications to accommodate different edge banding materials, panel sizes, and additional features. Please contact us to discuss your specific needs.

What is the lead time for delivery?

The standard lead time for the Bestin Automatic Edge Banding Machine is approximately 4-6 weeks from the order confirmation date. Lead times may vary based on customization requirements and current production schedules. Learn More →