Edge banding is an essential finishing technique in woodworking.

It can make the wood panel look polished to raw edges and enhance the workpiece’s

durability.

Whether crafting custom furniture or working on cabinetry, the edge banding‘s quality

can significantly impact the final product.

If you want to get a beautiful edge banding, it is important to choose the right

portable edge bander.

In this article, we’ll explore what makes a best portable edge bander for

various woodworking projects, guiding you in getting the right portable edge

banding machine.

Table of Contents

1. What is a Portable Edge Bander?

A portable edge bander is a compact machine.

It was

designed to apply edging materials like PVC, wood veneer, or melamine to the

edges of wood panels.

Portable

edge banders offer more flexibility compared to fixed edge banders as they are

easy to move around workshops or take to job sites.

It makes

them ideal for smaller shops or on-site work.

2. What Should You Consider When You Buy A Portable Edge Bander?

When buying a portable edge bander, there are some factors you should consider:

● Temperature Control

It allows you to adjust the heat applied to the adhesive, ensuring a strong bond between the edge band and the panel.

When you

work on edge banding, that is crucial precision in temperature control,

especially when working with different materials.

● Glue Pot Capacity

The glue pot’s size determines how much edging you can apply before needing to refill.

A larger

glue pot is beneficial for extended work sessions, reducing downtime and

increasing productivity.

● Feed Speed

The edge band’s feed speed will impact both the quality and efficiency of the process.

Machines

with adjustable feed speeds allow you to tailor the application pace to the

material and project complexity.

● Compatibility with Various Materials

A versatile edge bander should handle a range of materials, including PVC, ABS, wood veneer, and melamine.

It can

ensure that you can process various projects with a single machine.

● Portability and Weight

A portable edge bander’s advantage is its mobility.

It is

important to make a machine lightweight.

A

lightweight machine makes it easier to transport and use in different

locations.

3. Portable Edge Bander’s Advantages

Portable edge banders offer several advantages, making them a popular choice for many woodworkers:

● Versatility in Various Work Places

Whether in a small workshop or on a construction site, a portable edge bander adapts to different settings, providing flexibility that stationary models cannot match.

● Space-Saving Benefits

For woodworkers with limited shop space, a portable model can be stored away when not in use, freeing up valuable work areas.

● Cost-Effectiveness

Portable edge banders are generally more affordable. It can offer an economical option without sacrificing quality.

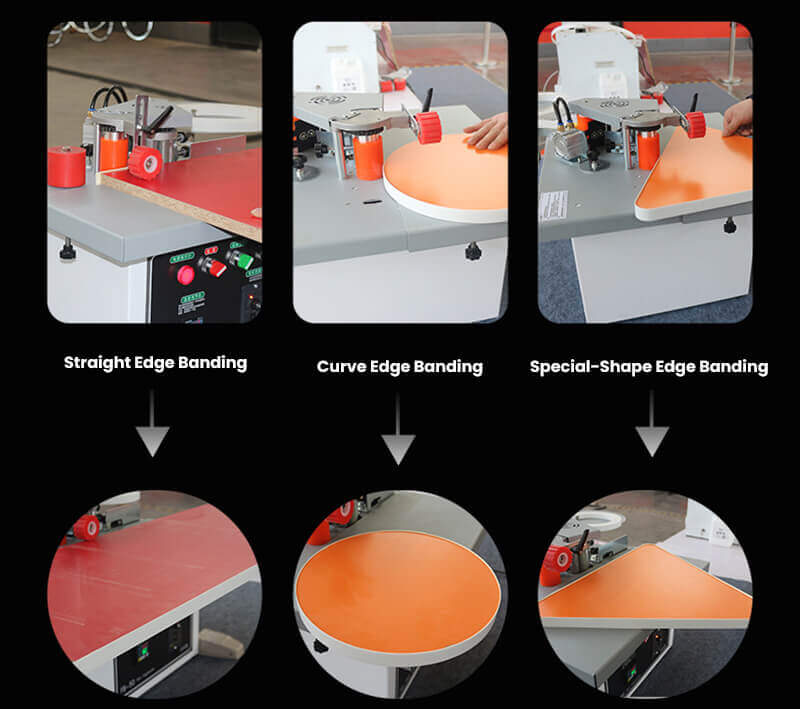

● Working On Multiple-shaped Wood Boards

The

portable edge bander can be used on multiple-shaped wood boards, including

straight, curved, or irregularly shaped edges.

4. Top Portable Edge Bander Brands

There are some portable edge banding machine brands, you can choose from them.

● Features and Specifications:

- Features and Specifications:

- Weight: 7.9 kg (17.4 lbs)

- Glue type: EVA and PUR hot melt adhesives

- Edge height range: 18–65 mm

- Edge thickness: 0.5–3.0 mm

- Temperature range: 100–210°C (212–410°F)

- Used: Compatible with a wide range of materials including PVC, wood veneer, and ABS.

● Pros:

- Excellent build quality and durability.

- Precise temperature control for consistent edge bonding.

- Versatile for a variety of materials and edge thicknesses.

- Integrated dust extraction system.

● Cons:

Higher price point compared to other models.

- Requires more maintenance due to advanced features.

● Features and Specifications:

Double Insulation: Yes

- Input Power: 1500 W

- Maximum Edgebanding Width: 2″ (50 mm)

- Minimum Edging Thickness: 0.4 mm

- Maximum Edging Thickness: 1 mm

- Temperature Settings:

- Step One: 570°F (300°C)

- Step Two: 1,000°F (525°C)

- Air Delivery: 16 cubic feet per minute (400 liters per minute)

- Weight: 6 lbs (2.7 kg)

● Pros:

Accurate Tape Tracking: The unit’s unique ability to track tape on the board, thanks to rubber clamps that hug the board, ensures precise application and bonding. This feature is particularly beneficial for achieving professional results.

- Versatility in Material: Suitable for use with most types of pre-glued edging, including PVC, polyester, melamine, and wood veneer. It can handle materials up to 2″ wide, making it versatile for various projects.

- Lightweight and Portable: Weighing just 6 lbs (2.7 kg), this edgebander is easy to transport, making it ideal for both on-site and workshop use.

- Fast Setup: With a setup time of less than one minute, it allows for quick adjustments, improving productivity on the job.

- Temperature Control: The two-step temperature switch offers flexibility in applying different types of edging materials, ensuring strong adhesion with the appropriate heat setting.

- Precision in Shaped Pieces: Perfect for circular and shaped pieces with a minimum internal radius of 20 mm, making it highly adaptable for complex woodworking tasks.

- Edge Trimming System: Comes supplied with a practical edge trimming system, further enhancing its utility and convenience.

● Cons:

Limited Maximum Edging Thickness: The maximum edging thickness of 1 mm might be insufficient for users working with thicker materials, potentially limiting its application in some professional settings.

- Manual Operation: As a manual edgebander, it requires skill and steady hands to ensure consistent results, which may be challenging for beginners or those new to edge banding.

- Temperature Settings: Although the two-step temperature switch is useful, the lack of more granular control over temperature could be a limitation for some specific materials or projects that require precise heat settings.

- Air Delivery Needs: The air delivery requirement of 16 cubic feet per minute (400 liters per minute) may necessitate a high-capacity air source, adding to the operational costs and complexity.

- Limited Capacity Models: The AG98F model applies edging up to 1 mm thick, which might not be sufficient for certain applications. Users needing more capacity might have to consider upgrading to the AG98R or AG98E models.

● Features and Specifications:

Power: 15A, 110V, single-phase, 60 Hz

- Feed Motor: 15W

- Feed Rate: Variable, 6.5–20 feet per minute (FPM)

- Working Temperature:

- Mode 1: 250°–340°F

- Mode 2: 175°–310°F

- Warm-Up Time: 4 minutes

- Required Surface Temperature: 75°–90°F

- Tape Width: 3/8″–2-1/2″

- Tape Thickness: 1/64″–1/8″

- Glue Pot Capacity: 13-1/2 oz.

- Overall Size: 14″ W x 12″ D x 14″ H

- Approximate Shipping Weight: 42 lbs.

● Pros:

-

Highly Portable: Ideal for on-site jobs, combining the power of a stationary

edgebander with the convenience of portability. - Comprehensive Functionality: Capable of handling various surfaces, including the complex task of edging inside corners, which many other portable edgebanders struggle with.

- User-Friendly Design: The easy-to-use controls, digital display, and variable speed control make it accessible for users of all experience levels.

- Safety Features: The glue pot heater’s ON/OFF switch enhances safety, while the long

power cord provides flexibility in movement without compromising safety. - Extended Use: The table-mounting option gives users the flexibility to switch between

portable and stationary setups depending on the project’s needs.

● Cons:

Weight: At 42 lbs, the G0825 is relatively heavy for a portable tool, which might be cumbersome for some users to transport frequently.

- Warm-Up Time: The 4-minute warm-up time, while not excessive, might be a slight inconvenience for those who require quick, on-the-go operation.

- Tape Thickness Limitation: The maximum tape thickness of 1/8″ might not be sufficient for all types of projects, potentially limiting its use in certain professional applications.

- Initial Cost: While feature-rich, the G0825 might represent a higher upfront investment compared to more basic models, which could be a consideration for hobbyists or small businesses.

- Complexity for Beginners: Despite its user-friendly features, the combination of variable speed, temperature controls, and additional accessories might present a learning curve for beginners.

● Features and Specifications:

- Output Power: 855 W

- Glue Pot Capacity: 400 ml

- Warm-up Time: 4 minutes (120°C / 250°F)

- Working Temperature: 120°C – 200°C (250°F – 390°F)

- Feeding Speed: 4.0 M/min (13 Ft/min)

- Tape Thickness: 0.4 – 3 mm

- Tape Width: 10 – 65 mm

- Temperature Control: Yes

- Net Weight: 8.7 kg

● Pros:

Adjustable Glue Pot Handle: The glue pot handle can be adjusted to two positions. It is particularly useful when dealing with workpieces that might interfere with the standard position, enhancing the flexibility of the machine.

- Versatile Edgebanding: Capable of handling straight-line and contoured surfaces, the BR300 is suitable for a wide range of workpieces. It can work on materials with an inner radius as small as 25mm (1″), making it versatile enough for various woodworking tasks.

- Material Compatibility: The BR300 is compatible with PVC, melamine, laminate, and wood edgebands, with a thickness range of 0.4mm to 3mm and a width range of 10mm to 65mm. This broad compatibility ensures that it can be used for a variety of projects.

- Angle Adjustment: The machine can operate on surfaces tilted between 75° and 90°, allowing it to handle beveled surfaces as efficiently as perpendicular ones.

- Durability and Continuous Operation: Unlike many portable edgebanders, the BR300 is built to withstand continuous operation without the need for cool-down periods. This makes it highly reliable for long work sessions.

- Portable and Stationary Use: The BR300 comes with a durable and lightweight case, making it easy to transport. For stationary use, workpieces can be secured with optional clamping kits or mounted on a stationary worktable, adding to its versatility.

● Cons:

Limited Digital Features: The BR300 lacks a digital display and control, which are features that some users might prefer for more precise temperature and speed adjustments. This might limit the machine’s appeal to those looking for advanced digital functionality.

- Warm-up Time: The machine requires about 20 minutes to warm up from a cold start, which might be seen as a drawback for users who need to begin their work immediately. However, this can be mitigated by refilling the glue pot when it is still warm.

● Features and Specifications:

Product Number: MAK03026

- Weight: 114 lbs

- Brand: Richelieu

- Voltage: 127 V

- Power: 1.3 W

- Width: 3 in

● Pros:

Precision and Control: The Richelieu Portable Edgebander offers a high level of precision, thanks to features like the integrated manual cutter, inner guide, and tape guide. These ensure a consistent and professional finish on all workpieces.

- Ease of Use: With an easy and fast setup process, even less experienced users can quickly become proficient with this machine. The various guides and supports make it straightforward to achieve high-quality results.

- Portability: Despite its relatively heavy weight, the retractable legs and compact design make this edgebander highly portable, suitable for both workshop and on-site use. The fact that it can fit in a standard car trunk is a significant advantage for mobile professionals.

- Versatility: The variable speed controller and ability to handle tapes up to 3mm thick make this machine versatile, capable of handling a wide range of edgebanding tasks. It’s equally adept at working with different materials, from PVC to wood veneer.

- Safety and Durability: The CA/UL rating and upgraded electronics ensure that the Richelieu Portable Edgebander is safe to use and built to last, providing peace of mind to its users.

● Cons:

Power Output: With a power output of only 1.3 W, some users might find this machine less powerful compared to other models in its class. This could affect its performance on tougher materials or larger projects.

- Initial Cost: Given its features and build quality, the Richelieu Portable Edgebander might represent a higher upfront investment. This could be a consideration for hobbyists or small businesses with tighter budgets.

● Features and Specifications:

Voltage: 220V

- Heating Time: 5-8 minutes

- Rated Power: 1.2 kW

- Glue Volume: 1000 ml

- Speed Model: Stepless Speed Regulation

- Edge Type: Straight, Curve

- Gluing Type: Double-sided gluing

- Belt Breaking Type: Manual

● Pros:

Versatile Edge Types: Supports both straight and curved edges, providing flexibility for various woodworking projects.

- Double-Sided Gluing: Ensures a strong bond by applying adhesive on both sides, enhancing durability.

- Stepless Speed Regulation: Allows precise control of edge speed, making it adaptable to different materials and project requirements.

- Compact and Lightweight: At 14 kg, it’s relatively easy to transport and set up, making it ideal for on-site jobs.

- Quick Heating Time: With a heating time of 5-8 minutes, the machine is ready to use quickly, improving efficiency.

- Large Glue Volume: The 1000 ml glue capacity reduces the need for frequent refills, allowing for extended operation without interruptions.

- Continuous Working Time: Capable of running continuously for up to 12 hours, making it suitable for large-scale projects.

● Cons:

Manual Belt Breaking: The manual belt-breaking type may require more user intervention and can slow down the workflow compared to automated options.

● Features and Specifications:

Total Power: 1000W

- Heating Time: 5-10 minutes

- Air Source Pressure: 0.3-0.6 MPa

- Edge Strip Width: 10-60 mm

- Glue Pot Volume: 1000 ml

- Edge Strip Thickness: 0.3-2 mm

- Weight: 24 kg

- Edge Capability: Suitable for straight, curved, and shaped boards

● Pros:

Versatile Edge Banding: Capable of handling straight, curved, and shaped boards, offering flexibility for various applications.

- Large Glue Pot Volume: The 1000 ml glue pot allows for extended operation without frequent refilling, increasing productivity.

- Wide Edge Strip Range: With a width capacity of 10-60 mm and thickness handling of 0.3-2 mm, this machine can accommodate a variety of edge strips.

- Adjustable Edge Speed: The speed range of 2-6 m/min allows for precise control, catering to different materials and project requirements.

- Compact Design: With dimensions of 50 x 50 x 45 cm, the machine is relatively compact, making it suitable for smaller workspaces.

- Stable Air Pressure: The air source pressure range of 0.3-0.6 MPa ensures reliable operation of pneumatic components, contributing to smooth performance.

● Cons:

Limited Edge Speed: While the adjustable speed is beneficial, the maximum speed of 6 m/min might not be fast enough for high-volume production environments.

- Air Source Dependency: The need for an external air source with specific pressure requirements could limit the machine’s portability and add to operational complexity.

5. How to Maintain Your Portable Edge Bander?

● Regular Cleaning and Lubrication

Clean the glue pot regularly to prevent buildup.

- Lubricate moving parts according to the manufacturer’s instructions to maintain smooth operation.

● Inspection for Wear and Tear

Regularly check for worn parts such as the feed rollers and the heating element.

- Replace any damaged components promptly to avoid further issues.

● Proper Storage Practices

Store in a dry, dust-free environment.

- Keep the machine covered when not in use to prevent dust accumulation.

6. Common Mistakes to Avoid

Overheating the Glue Pot: Always monitor temperature settings.

- Incorrect Feed Speed Settings: Match the feed speed with the material and edge thickness.

- Neglecting Regular Maintenance: Follow the maintenance schedule to prevent malfunctions.

- Using the Wrong Adhesive for Specific Materials: Always check compatibility between adhesive and material.

7. How to Maximize the Efficiency of Your Portable Edge Bander?

● Tips for Faster Setup:

Prepare all materials and set up the machine before starting the edge banding process.

- Preheat the glue pot while preparing the edges to save time.

● Optimizing Temperature Settings:

Adjust the temperature according to the material’s requirements to ensure optimal adhesion.

● Best Practices for Edging Different Materials:

Use lower temperatures for thinner edges and higher temperatures for thicker materials.

- Ensure consistent pressure for even glue application.

● Enhancing Precision with Proper Technique:

Maintain a steady hand and consistent speed when feeding material through the machine.

- Practice on scrap materials before working on the final product.

8. Safety Tips When Using a Portable Edge Bander

● Protective Gear Recommendations:

Always wear safety glasses and heat-resistant gloves.

- Use ear protection if the machine is loud.

● Safe Handling and Operation:

Never touch the glue pot or heating element while the machine is on.

- Keep hands away from the feed rollers during operation.

● Emergency Procedures for Malfunctions:

Turn off the machine immediately if you notice any unusual sounds or smells.

- Unplug the machine before attempting any repairs.

9. Portable Edge Bander Accessories

Additional glue pots for quick adhesive changes.

- Edge trimmers for a clean finish.

- Optional Add-Ons for Enhanced Performance: Extension tables for larger panels.

- Specialized rollers for different edge materials.

10. Conclusion

A portable edge bander is an invaluable tool for woodworkers making cabinets or interior decorations.

By

understanding the key features, benefits, and maintenance requirements of

portable edge banders, you can select the best model to suit your specific

needs.

Whether

you’re working in a compact workshop or on-site, a

portable edge bander will ensure that your projects are completed perfectly.