Discover the cutting-edge solution for precision woodworking with our comprehensive guide on the best sliding table saws.

Whether you’re a seasoned cabinet maker, a professional woodworker, or a serious DIY enthusiast, this guide is designed to help you choose a machine that elevates your craftsmanship, maximizes productivity, and boosts safety in your workshop.

In this in-depth article, we’ll explore the core benefits of sliding table saws, outline must-have features and technologies, and present a detailed comparison of the top 10 brands on the market today.

Our expert analysis is tailored to answer your questions, address your concerns, and guide you through a seamless buying experience.

Let’s get started!

Table of Contents

1. Introduction

A sliding table saw is a game-changer for any woodworking operation.

Unlike conventional table saws, these machines feature a sliding table mechanism that allows for precise, long cuts on wide panels and large sheet goods.

The enhanced control and accuracy not only boost efficiency but also elevate the quality of your finished products.

1.1. Why Choose a Sliding Table Saw?

- Precision and Accuracy:

This is essential for producing high-end cabinetry and furniture where detail matters.

- Enhanced Safety:

These improvements reduce the risk of accidents, making your workshop safer for operators.

- Increased Productivity:

Whether you’re working on custom projects or mass production, a sliding table saw can help streamline your workflow.

- Versatility:

Their versatility makes them an ideal choice for diverse woodworking projects.

2. Key Features and Technologies

When searching for the best sliding table saw, you want a machine that not only performs flawlessly but also integrates innovative technologies to enhance your productivity.

Here’s what to look for:

2.1. Automated Feeding Systems

Automated feeding systems use conveyor belts or rollers to transport panels steadily through the cutting area. This ensures:

- Consistent Alignment: Every cut is precise and uniform.

- High Throughput: Ideal for busy shops where time is money.

- Reduced Manual Handling: Less operator fatigue and fewer errors.

2.2. Advanced Blade Technologies

- Laser-Guided Precision: Some models offer laser alignment for optimal blade positioning.

- Variable Speed Options: Adjust the cutting speed based on material type and thickness.

- High-Quality Materials: Blades made from carbide-tipped or high-speed steel ensure longevity and cleaner cuts.

2.3. Innovative Sliding Mechanism

The heart of these machines is the sliding table:

- Smooth, Accurate Movement: Precision rails and ball bearings reduce friction, ensuring a steady slide.

- Adjustable Travel Length: Accommodate various sheet sizes from 4×8 feet to custom dimensions.

- Enhanced Stability: Minimized vibration for perfect cut quality even on large panels.

2.4. Precision Fence and Alignment Systems

A robust fence system is crucial for achieving straight, repeatable cuts:

- Adjustable Fences: Easily fine-tune the fence position for different cutting angles.

- Digital Alignment Tools: Some saws offer digital readouts for perfect settings every time.

- Integrated Measuring Scales: Built-in scales help maintain accuracy throughout the cutting process.

2.5. Safety Features

Safety is paramount in any woodworking environment. Look for:

- Blade Guard Systems: Protect operators from accidental contact.

- Emergency Stop Buttons: Quick shutdown options for immediate response in emergencies.

- Flesh Detection Technology: Some high-end models, like those from SawStop, can detect contact with human flesh and stop the blade instantly.

2.6. Dust Extraction and Environmental Controls

Maintaining a clean workspace is essential for both quality and safety:

- Integrated Dust Collection Systems: Capture sawdust at the source to keep your environment clean.

- HEPA Filters: Some models include advanced filtering systems to minimize airborne particulates.

- Noise Reduction Features: Enhanced insulation and damping systems reduce operational noise.

2.7. User-Friendly Control Panels

Modern sliding table saws feature intuitive control interfaces:

- Touchscreen Displays: Easily adjust settings and monitor machine status.

- Programmable Cutting Profiles: Save and recall frequently used settings to reduce setup time.

- Remote Diagnostics: Some models offer IoT connectivity for real-time monitoring and troubleshooting.

3. Top 10 Best Sliding Table Saw Brands Compared

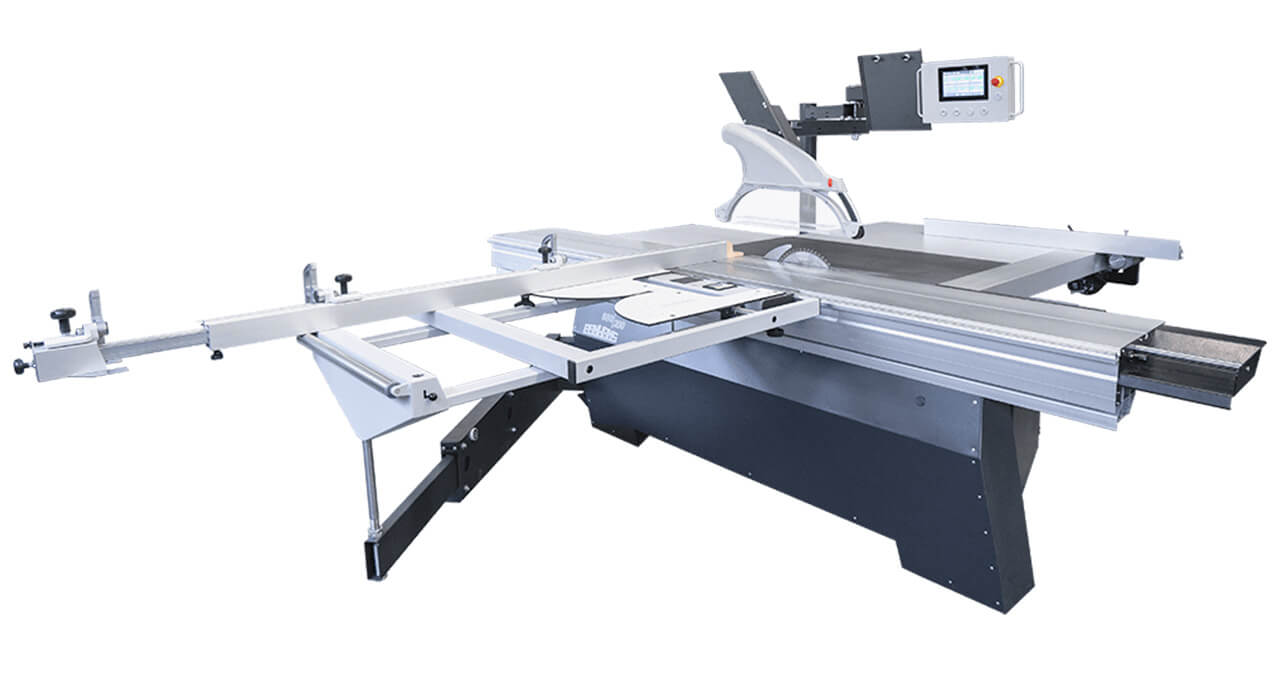

3.1. Format 4

Overview:

The all-new Kappa 590 Premium sets a new benchmark with its revolutionary twin-pivot unit, offering a total swivel range of 92° and an impressive cutting height of 202 mm for 550 mm diameter saw blades. Built for high-volume production, it makes internal miter and simple compound cuts effortless.

Key Features:

- Twin-Pivot Unit: Full swivel range of 92° enables diverse cutting angles.

- High Cutting Height: Accommodates saw blades up to 202 mm high.

- Synchronous Motor: Provides continuously adjustable speeds from 2,000 to 5,000 rpm.

- Poly-V-Belt Technology: Guarantees constant high performance and exceptional power transmission.

- Ergonomic Controls: A central operating unit with a 15″ touch screen, featuring a graphical user interface, multiple programs, USB interface, and network connectivity.

- Format-4 Quality: Incorporates the proven virtues and quality features of the Format-4 brand.

Pros:

- Unparalleled precision and versatility for complex cuts.

- Intuitive, user-friendly control interface.

- Robust construction suitable for industrial environments.

Cons:

- Premium pricing may be a consideration for smaller operations.

- Regular calibration is required for optimum performance.

Ideal For:

High-production environments where precision and efficiency are paramount.

3.2. Altendorf Sliding Table Saw WA8TE

Overview:

Engineered for heavy industrial use, the Altendorf WA8TE features a 3200 mm sliding table for a generous 10-foot cutting capacity and accommodates blades up to 400 mm, delivering a cutting depth of up to 4.9 inches. Its direct vertical guidance system ensures chip-free cuts—even with tilting—across challenging materials.

Key Features:

- Large Sliding Table: Provides extensive 3200 mm travel for oversized panels.

- Blade Capacity: Supports up to 400 mm diameter blades, enabling deep cuts (up to 4.9″).

- Direct Vertical Guidance: Guarantees chip-free, clean cuts on melamine, vinyl, HPL, and veneered panels.

- Electric Adjustments: Automated rise, fall, and tilting adjustments of the saw carriage for precision setup.

- Integrated Scoring Unit: Features automatic adjustments even when the scoring saw is in operation.

Pros:

- Exceptional cutting capacity and versatility.

- Superior chip management for clean, precise work.

- Advanced automation reduces manual intervention.

Cons:

- Higher investment cost.

- Requires operator training to fully leverage its advanced features.

Ideal For:

Industrial-grade applications such as high-end cabinetry, veneered panel processing, and large-scale production facilities.

3.3. SCM SI300 Nova Panel Saw

Overview:

The SCM SI300 Nova stands out as an excellent industrial panel saw that marries advanced manufacturing techniques with high precision. Its anodized sliding carriage on hardened steel guides ensures durability and flawless performance.

Key Features:

- Anodized Sliding Carriage: Ensures smooth motion on hardened steel guides.

- 10-Year Warranty: Confidence-inspiring warranty on the sliding mechanism.

- Operator-Centric Design: Manual lifting and tilting are positioned on the operator’s side, with mechanical readout for accurate adjustments.

- Independent Scoring Unit: External settings for precise scoring.

- Global Support: Manufactured to certified quality standards with efficient worldwide after-sales service.

Pros:

- High precision and quality built into every cut.

- Robust design with long-term warranty support.

- Easy adjustments and maintenance.

Cons:

- The digital interface may have a slight learning curve.

- Frequent maintenance checks might be needed for optimal performance.

Ideal For:

Woodworkers seeking a balance between quality, accuracy, and value in both low- and high-volume production settings.

3.4. Cantek D405ANC 1-Axis Sliding Table Saw

Overview:

The Cantek D405ANC is celebrated for its high-precision performance, especially for cutting sheet materials used in kitchen cabinetry, furniture, and millwork. Its powerful 7.5 HP main motor paired with a 1 HP scoring motor makes demanding operations a breeze.

Key Features:

- Powerful Dual Motors: 7.5 HP main motor with a separate 1 HP scoring motor for enhanced performance.

- Ergonomic Control Panel: Simplifies setting rip width, blade height, and blade angle.

- Accurate Crosscut Miter Fence: Enables fast length and angle adjustments for precision cuts.

- Robust Build: Designed to handle demanding industrial applications with consistent performance.

Pros:

- High precision and reliable performance in specialized applications.

- User-friendly controls and intuitive adjustments.

- Ideal for detailed cabinetry and furniture production.

Cons:

- May have limited versatility compared to multi-axis machines.

- Not designed for processing the largest panel sizes.

Ideal For:

Specialized woodworking operations and professional shops focused on precision millwork and cabinetry.

3.5. Martin T60C Sliding Table Panel Saw

Overview:

Manufactured in Germany to the highest premium standards, the Martin T60C offers an outstanding balance between quality, price, and performance. It’s perfect for cutting wood, plastics, and composites up to 130 mm high with incredible precision.Key Features:

- Innovative Control System: A 3.5″ eye-level controller that guides the operator through each process.

- Powerful Motor: Equipped with a 5.5 kW (7.5 HP) S1 motor with electronic soft start braking.

- Triple Speed Options: Offers multiple speeds to suit various materials and cutting tasks.

- Large Rip Capacity: Provides a 1350 mm rip capacity along with hand-wheel fence adjustments and digital readouts.

Pros:

- Excellent precision and ease of operation.

- Robust and versatile for a wide range of materials.

- Competitive pricing for premium performance.

Cons:

- May require skilled operation for optimal results.

- Higher operational costs over prolonged usage.

Ideal For:

Custom cabinetry, furniture production, and high-volume workshops where precision and user-friendliness are key.3.6. ITECH SEGA 315 Panel Saw

Overview:

The ITECH SEGA 315 is designed for large panels up to 10′ in length with a 3200 mm cutting capacity. It combines power, safety, and convenience with an adjustable overhead guard and extensive aluminum sliding table for maximum support.

Key Features:

- Large Cutting Capacity: Supports panels up to 3200×375 mm for wide-scale operations.

- Powerful S1 Rated Motors: 5.5 HP main motor with an independent, continuous-rated scoring motor.

- Adjustable Overhead Guard: Enhances safety with adjustable linear bearings and an extraction connection.

- Robust Support Frame: Provides exceptional panel stability and accurate mitering.

Pros:

- High capacity for large, continuous panels.

- Strong, efficient cutting performance.

- Comprehensive safety and support features.

Cons:

- The machine’s size may require more space in smaller workshops.

- Periodic calibration may be necessary for optimal performance.

Ideal For:

Industrial woodworking facilities and fabrication shops that require high-capacity, precise panel cutting.

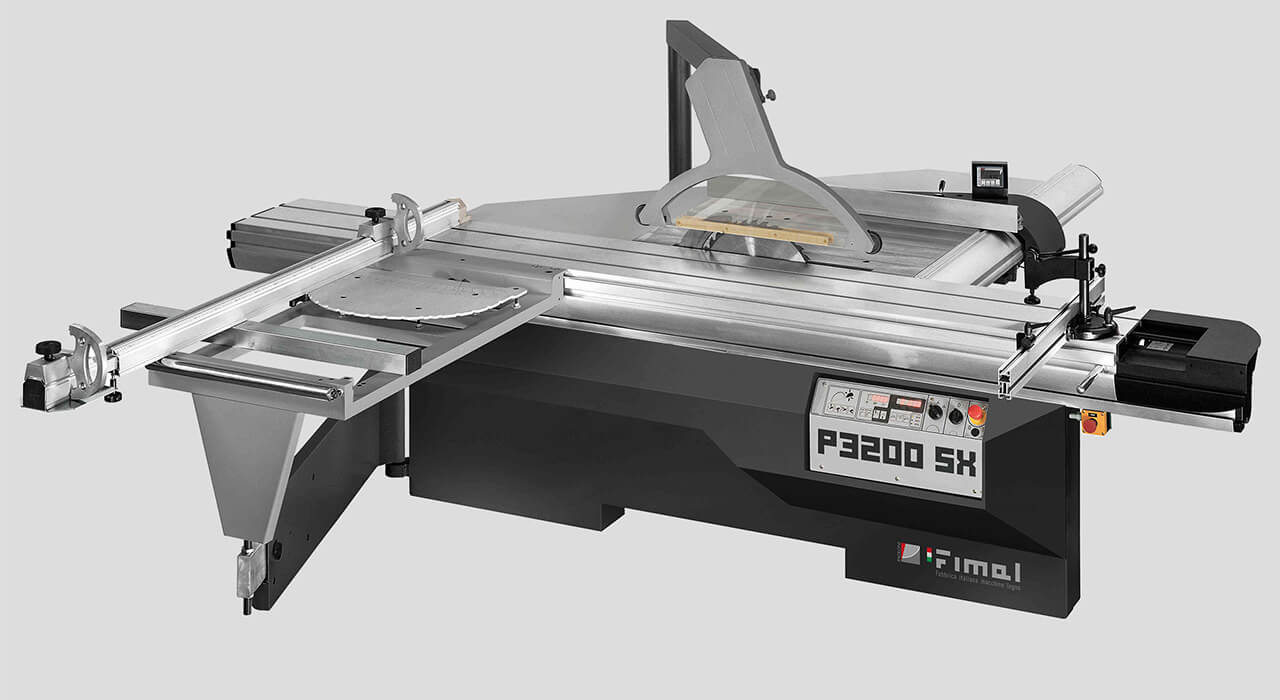

3.7. Fimal P3200SX Sliding Table Saw

Overview:

The Fimal P3200SX represents engineering excellence with its superior carriage sliding system. Large-diameter bearings and precision-ground tracks ensure exceptional stability, virtually eliminating vibrations for a perfectly straight cut.

Key Features:

- Superior Sliding Carriage: Utilizes large-diameter bearings on prismatic, hardened tracks.

- Vibration-Free Operation: Mechanically engineered for exceptional stability and precision.

- Durable Construction: Designed to maintain glue adhesion and consistent performance over time.

- Precision Machining: Produced with numerically controlled machines for unparalleled accuracy.

Pros:

- Industry-leading stability and precision.

- Excellent for continuous, high-quality cuts.

- Built for heavy industrial use with minimal vibration.

Cons:

- Premium pricing may be restrictive for smaller operations.

- Advanced features may necessitate specialized maintenance.

Ideal For:

High-end production environments and professional woodworkers demanding flawless cuts and top-tier precision.

3.8. PANHANS Sliding Panel Saw 680|200

Overview:

The PANHANS 680|200 is a precision tool designed for professionals who require exceptional accuracy. With its maintenance-free aluminum sliding table and intuitive 4.7″ touch control, this saw excels in complex cutting tasks.

Key Features:

- Maintenance-Free Aluminum Table: Offers a 3200 mm cutting length with minimal upkeep.

- Intuitive Touch Control: A 4.7″ interface mounted on the machine base for effortless operation.

- Electromotive Adjustments: Height and angle adjustments are automated for precision settings.

- Wide Tilting Range: Supports a 0–46° tilt, making it versatile for various cutting requirements.

- Quick Change Blade System: The APA quick change system simplifies blade swaps.

Pros:

- High precision with automated adjustments.

- Excellent for large-format and complex panel cutting.

- User-friendly interface streamlines workflow.

Cons:

- Bulkier design may be less ideal for compact workshops.

- Requires robust power supply due to high automation features.

Ideal For:

Industrial fabricators and professional woodworking operations where precision and versatility in cutting are critical.

3.9. Maksiwa Sliding Panel Saw BMS.3200.IR

Overview:

The Maksiwa BMS.3200.IR is a custom-built solution for high-volume production, engineered for precision cutting at various angles. Its powerful 5 HP motor, cutting guides, and advanced safety features deliver unmatched performance.

Key Features:

- Powerful Motor: Equipped with a 5 HP motor that supports a maximum cut depth of 100 mm (4 inches) at 90°.

- Versatile Cutting Angles: Custom-built to deliver precise cuts at multiple angles with exceptional accuracy.

- Low Noise Operation: Operates at 76.5 dB when idle and up to 110 dB during cutting—minimizing disruption.

- Comprehensive Safety: Features cutting guides, miter guide, and blade guard for safe operation.

Pros:

- Superior performance for high-volume, industrial applications.

- Robust construction ensures long-lasting reliability.

- Advanced safety features protect both the operator and the machine.

Cons:

- Advanced configuration requires expert setup and training.

- Investment cost is on the higher side.

Ideal For:

Large-scale production environments and professional workshops seeking robust, industrial-grade performance.

3.10. BestIn BSTS32H Sliding Table Saw

Overview:

The SMV8D-XP PANEL SAW delivers an impressive mix of digital precision and efficient design. With motorized up/down functions for both the main and scoring saws, as well as electrical tilting for up to 45°, this model is engineered to optimize workflow and cut with exceptional accuracy.

Key Features:

- Motorized Up/Down Mechanism: For both the main saw and scoring saw, ensuring smooth operation.

- Electrical Tilting: Offers precise control with tilting up to 45°.

- Digital Rip Fence: Motorized adjustments for consistent, accurate cuts.

- Optimized Control Software: PC-based control that automatically optimizes layout and processing files.

- Robust Specifications: Maximum main saw blade diameter of 400 mm and overall dimensions designed for high capacity.

Pros:

- Excellent digital integration for precise, repeatable cuts.

- Streamlined controls reduce operator setup time.

- Competitive pricing without sacrificing advanced functionality.

Cons:

- Might lack the heavy-duty capacity of some larger industrial models.

- Requires periodic software updates and calibration.

Ideal For:

Small to medium production facilities seeking a modern, efficient, and cost-effective panel saw with advanced digital controls.

4. What Is The Difference Between A Sliding Table Saw From Other Table Saws?

Firstly,

the most obvious difference between a sliding table saw and other table saws is

the sliding table.

A

sliding table saw was equipped with a large, flat table that is attached to the

saw.

Its table

can slide back and forth on rails, allowing the user to cut large pieces of

wood or other materials easily and accurately.

And

table saws have a fixed table that can make it difficult to cut large pieces of

material.

Second,

the difference between a sliding table saw and other table saws are the

accuracy of the cuts.

With a

sliding table saw, the woodworker can make precise cuts with ease, thanks to

the sliding table and other advanced features.

Because

the sliding table can always hold the material in the correct position, it can

reduce the risk of mistakes or errors in the cutting process.

Many

sliding table saws have features such as digital readouts and rail guides,

which further enhance the accuracy of the cuts.

Additionally,

sliding table saws can be used to make many different types of cuts, such as

cross cuts, rip cuts, angled cuts, and more.

5. What Are The Main Parts Of The Sliding Table Saw?

5.1. Miter Gauge

The

miter gauge is an important component of a sliding table saw that helps the

user make accurate angled cuts.

It is a

guide that allows the user to adjust the angle of the cut to create precise and

intricate shapes.

A

well-designed miter gauge can offer a range of angles and is easily adjustable,

making it an essential tool for any woodworker.

5.2. Rip Fence

The rip

fence is another critical component of a sliding table saw that ensures

accuracy and consistency in straight cuts.

It is a

guide that runs parallel to the saw blade and helps to keep the material being

cut in a straight line during cutting.

A good

quality rip fence is adjustable, locks securely in place, and can be easily

removed when needed.

5.3. Bevel System

The

bevel system of a sliding table saw allows the user to tilt the blade to make

angled cuts, creating beveled edges and other intricate shapes.

It is a

crucial component of the saw that enables the user to create a variety of cuts

with precision and accuracy.

The

bevel system can also include features such as angle indicators and positive

stops, making it easier for the user to achieve the desired angle.

5.4. Blade Group

The

blade group consists of the main saw and the scoring saw.

The main

saw is responsible for making the main cut, while the scoring saw helps to

prevent tear-out and improve the quality of the cut.

This

component is essential for achieving clean and precise cuts, especially when

working with fragile or delicate materials.

5.5. Blade Guard

The

blade guard is an essential safety feature of a sliding table saw that helps to

prevent injury by covering the blade during cutting.

It is a

device that surrounds the blade and prevents the user from coming into contact

with it during use.

Additionally,

it helps to prevent sawdust and debris from flying up and causing injury,

making it an essential component for safe operation.

6. How to Choose the Best Sliding Table Saw for Your Workshop

Selecting the right sliding table saw involves understanding your specific needs and evaluating how each machine’s features align with your production goals.

Here are key factors to consider:

6.1. Assess Your Production Needs

- Volume: Determine the number of panels or pieces you need to cut daily. High-volume production requires faster, more automated machines.

- Material Types: Consider the types of materials you will be cutting—hardwoods, plywood, MDF, or composites—and ensure the saw is compatible with them.

- Precision Requirements: For fine cabinetry and intricate joinery, a saw with advanced digital controls and precision fences is essential.

6.2 Budget and Investment

- Cost vs. Value: While premium models offer advanced features, many mid-range machines provide excellent performance at a lower cost.

- Long-Term Investment: Consider warranty, after-sales service, and maintenance support. A higher initial investment might save you costs in the long run by reducing downtime.

6.3 Space and Layout

- Workshop Size: Ensure that the sliding table saw will fit into your workshop without disrupting your workflow.

- Integration: If you have automated material handling or CNC systems, look for machines that integrate seamlessly with your existing setup.

6.4 Safety and Compliance

- Safety Features: Prioritize machines with advanced safety features like blade guards, emergency stop mechanisms, and flesh-detection technology.

- Regulatory Compliance: Ensure the machine meets industry standards and safety certifications (e.g., OSHA guidelines).

6.5 Ease of Use and Maintenance

- User Interface: Opt for machines with intuitive controls and digital interfaces that simplify operation.

- Maintenance: Look for models that offer easy access for cleaning, blade changes, and routine servicing.

7. Maintenance and Safety Tips for Your Sliding Table Saw

Maintaining your sliding table saw is key to ensuring consistent performance and longevity. Here are some expert tips:

7.1. Regular Cleaning and Inspection

- Dust Extraction: Clean dust and debris regularly using the built-in dust extraction system.

- Visual Inspection: Check for wear and tear on the sliding rails, fence, and blade guard.

7.2. Preventive Maintenance

- Lubrication: Regularly lubricate moving parts to ensure smooth operation.

- Blade Maintenance: Keep the blade sharp and properly aligned for clean cuts.

- Calibration: Periodically recalibrate digital controls and fences to maintain accuracy.

7.3. Safety Practices

- Operator Training: Ensure all operators are fully trained on safe operation and emergency protocols.

- Use of PPE: Always wear safety glasses, hearing protection, and dust masks.

- Emergency Procedures: Familiarize yourself with the machine’s emergency stop functions and maintain clear access to safety controls.

- For more detailed maintenance tips, see our Maintenance Guide.

8. To Sum Up

Choosing the right sliding table saw is not just about making a purchase—it’s an investment in the future success of your woodworking operations.

With enhanced precision, improved safety, and increased production capabilities, the best sliding table saw can redefine your workflow and help you achieve professional-grade results.

Don’t wait—upgrade your workshop today.

Get a Free Quote or Contact Us Now to speak with one of our experts and discover exclusive offers available for a limited time!