In the woodworking industry, efficiency and precision are paramount, especially when dealing with large-scale production.

A beam saw machine is a critical machine designed to cut large sheets of wood, particleboard, MDF, and other materials into smaller, manageable pieces with high accuracy.

This complete guide aims to walk you through everything you need to know about buying a beam saw machine, ensuring you select the best option for your specific needs.

Whether you’re a small workshop looking to scale up or an industrial manufacturer seeking to optimize operations, this guide will provide the insights you need to make an informed decision.

Featured Resource

Table of Contents

1. Understanding Beam Saw Machines

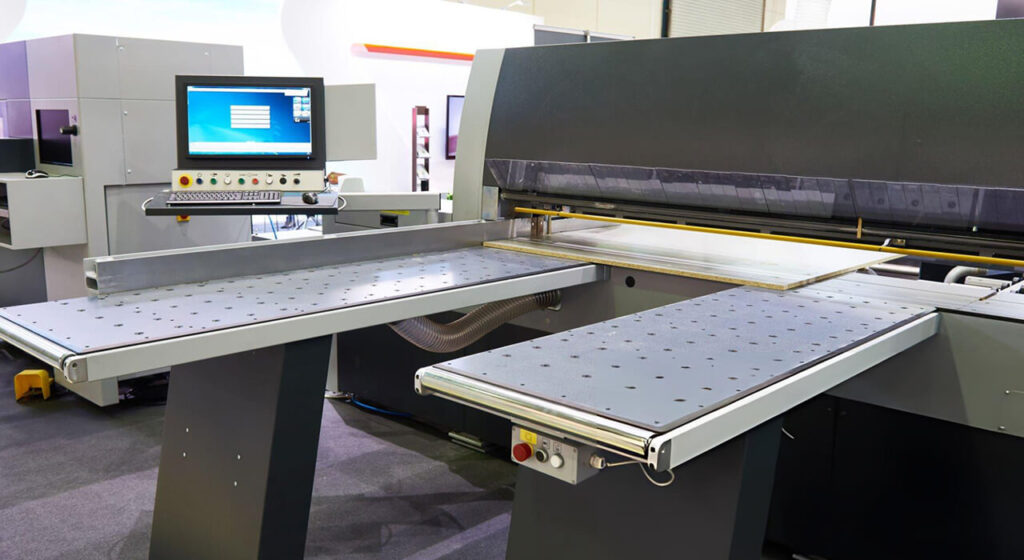

A beam saw machine is characterized by its overhead beam that supports the saw blade, which moves back and forth along a track to make precise cuts.

This design is particularly effective for cutting large panels, making it a staple in furniture manufacturing, cabinet making, and other wood-based product production.

The machine’s ability to handle high-volume cuts with repeatability makes it indispensable for industrial settings.

From the research, it’s clear that beam saw machines are not just tools but investments in productivity.

They are commonly used for cutting materials like plywood, MDF, and particleboard, and their applications extend to creating furniture parts, doors, windows, and building materials.

The automation level, whether manual, semi-automated, or CNC, significantly impacts their suitability for different production scales.

2. Types of Beam Saw Machines

2.1. Semi-Automated Beam Saws

2.2. Fully Automatic & CNC Beam Saws

For high-output environments, fully automatic and CNC (Computer Numerical Control) beam saw machines are the gold standard.

These machines are equipped with advanced software that automates the cutting process, from material feeding to final cut execution.

With CNC integration, you can program intricate cutting patterns and achieve exceptional repeatability.

Fully automatic beam saws are designed to handle continuous, heavy-duty production with minimal operator intervention, making them ideal for large manufacturing plants and industrial applications.

Additionally, beam saws can be categorized by configuration:

- Horizontal Beam Saws: The saw blade is mounted horizontally, and the material is placed on a table below the beam. This is common for cutting large panels and offers stability for precise cuts.

- Vertical Beam Saws: The saw blade is mounted vertically, and the material is fed through the side. These are less common but can be useful for specific cutting tasks, especially in space-constrained environments.

3. Key Components and Features

A beam saw machine’s performance is determined by its core components. Understanding these will help you assess which model meets your needs.

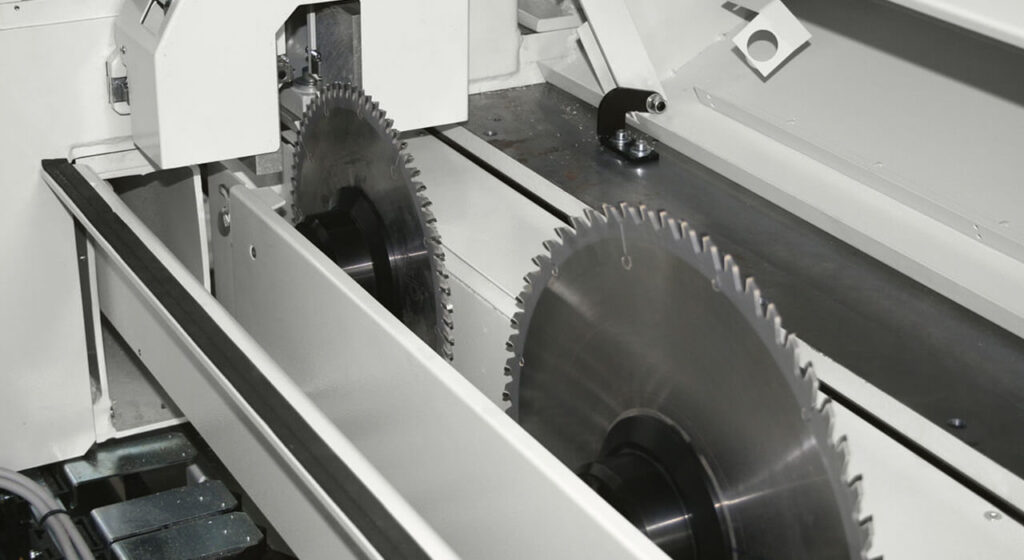

3.1. Saw Carriage and Cutting Unit

The saw carriage holds the cutting blade and moves it precisely along the designated path. High-quality beam saws feature a robust carriage system engineered to minimize vibration and ensure a straight, accurate cut.

Look for systems with high rigidity and smooth motion control to avoid any deviations that could compromise cut quality.

3.2. Clamping Systems and Pressure Beams

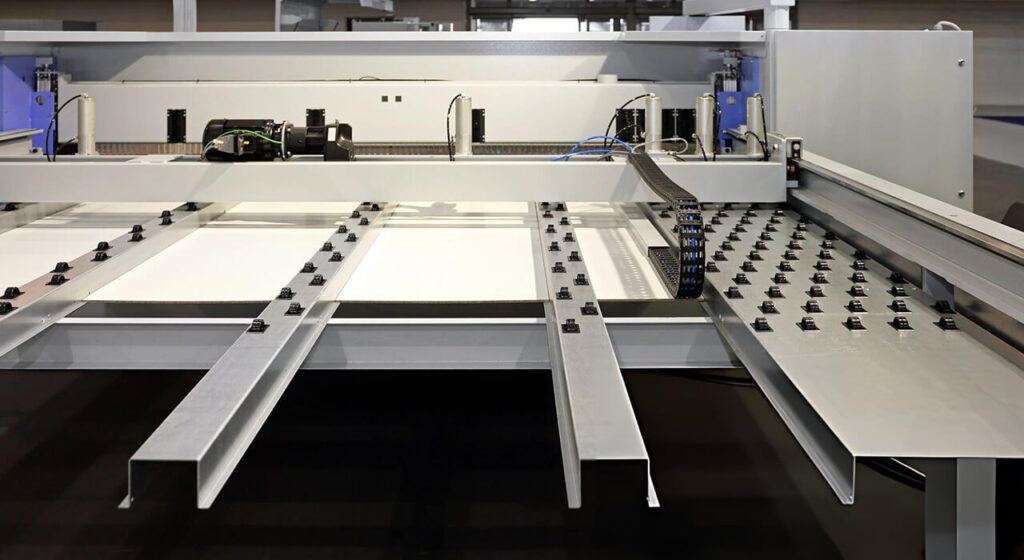

To achieve precise and repeatable cuts, the workpiece must remain firmly in place.

Advanced clamping systems, including pressure beams, are essential to prevent any material movement during the cutting process.

A reliable clamping mechanism not only enhances safety but also ensures that every cut is consistent and free from errors.

3.3. Worktables and Material Support

The worktable is where your material is positioned, and its design directly impacts cutting accuracy.

A flat, sturdy table equipped with material support systems helps reduce deflection and supports large panels during cutting.

Most of table are equipped with air flotation table, that can prevent scratching the board.

Look for models incorporating adjustable support features, which can be crucial when handling varied material sizes and thicknesses.

3.4. Control Panels and Software Integration

Modern beam saw machines come with digital control panels that provide intuitive operation and precise control over the cutting process.

Integration with specialized software enables automation of complex cutting patterns, optimizing material usage and reducing waste.

Features such as real-time monitoring, error detection, and adjustable feed rates contribute to a more efficient production process.

4. How to Choose the Right Beam Saw Machine

4.1. Assess Your Needs

- Determine your production volume: How many pieces do you need to cut per day or week?

- Identify the material types and sizes: Are you cutting plywood, MDF, or thicker materials like solid wood?

- Consider precision requirements: Do you need exact cuts for furniture parts or can there be some tolerance?

- Set a budget: What is your maximum spending limit, including ongoing costs?

4.2. Determine the Type of Machine

- For small to medium production with basic requirements, semi-automated beam saw might suffice, offering affordability and simplicity.

- For large-scale production requiring high precision and efficiency, a CNC beam saw is recommended, as it can handle complex cuts and large volumes with minimal operator intervention.

4.3. Evaluate Key Features

4.4. Research Brands and Models:

4.5. Consider Total Cost of Ownership:

5. Key Features to Look For

When buying a beam saw machine, several key features should be considered to ensure it meets your needs and provides long-term value. Here’s a detailed breakdown:

| Feature | Description |

|---|---|

| Cutting Capacity | Includes maximum cutting length, width, and height. Ensure it can handle your largest and thickest materials. |

| Cutting Speed and Precision | Faster speeds increase production rates, but precision controls like measurement systems ensure accuracy. |

| Automation Level | Choose between manual, semi-automated, or CNC based on production needs and budget. |

| Safety Features | Look for emergency stop buttons, guards, enclosures, and dust collection systems to protect operators. |

| Durability and Build Quality | High-quality materials ensure longevity. Check for warranties and manufacturer support. |

| Ease of Use and Maintenance | User-friendly controls reduce training time, and easy access to maintenance points ensures smooth operation. |

- Cutting Capacity: This is crucial as it determines the size of the material the machine can handle. For example, industrial beam saws from Original Saw Company (Five Things to Know Before Buying a Beam Saw) can make crosscuts from 60″-64″ with a depth of cut up to 8″, suitable for large materials like logs and trusses.

- Cutting Speed and Precision: The speed of the saw blade affects production rates, while precision controls, such as those in CNC models, ensure accurate cuts, which is vital for furniture and cabinet making.

- Automation Level: Manual machines are cost-effective for small operations, while CNC models, as described by Konetool (What Is A CNC Beam Saw?), offer advanced software for highly accurate and efficient cutting, ideal for large runs.

- Safety Features: Safety is paramount, with features like emergency stops and dust collection systems (mentioned in various manufacturer descriptions) helping maintain a safe workspace and reduce health hazards.

- Durability and Build Quality: High-quality materials, such as precision ground guide rods coated with hard chrome (seen in Capital Woods Machinery’s offerings Beam Saw), ensure the machine lasts longer and performs consistently.

- Ease of Use and Maintenance: Machines with intuitive controls and easy access to lubrication points, as highlighted in maintenance tips from Elephant CNC, reduce downtime and training costs.

6. Top Brands and Models

The market offers a variety of beam saw machines from reputable manufacturers, each with unique strengths. Here are some notable brands and models:

- SCM Group: Known for their Gabbiani beam saw range, including the Gabbiani P and Gabbiani S, which offer options from basic to fully automated, as seen on their product page (SCM Group Beam Saws).

- Holzma: Offers a variety of beam saws with advanced features like automatic optimization and high-speed cutting, suitable for large-scale production, as noted in WOOD TEC PEDIA (Beamsaw).

- Original Saw Company: Specializes in stationary beam saws effective for cutting logs, trusses, and other large materials, with models making crosscuts from 60″-64″, as detailed in their buying guide (Five Things to Know Before Buying a Beam Saw).

At our website, we carry a selection of top-quality beam saw machines.

Our team is dedicated to helping you find the perfect machine, offering expert advice and demonstrations to ensure you make the right choice.

7. Pricing, Financing, and Return on Investment (ROI)

Investing in a beam saw machine is a significant financial commitment, but the long-term benefits often far outweigh the initial expense. Here are some critical factors to consider regarding pricing and financing:

Pricing Factors

- Entry-Level Models: Ideal for smaller workshops or startups, entry-level beam saw machines typically range between $20,000 and $30,000. These models offer essential features and may have limited automation capabilities.

- Mid-Range Machines: For mid-sized operations, mid-range machines can cost between $30,000 and $50,000. They provide a good balance between automation, cutting capacity, and durability.

- High-End Models: Fully automatic or CNC-integrated beam saw machines can exceed $50,000, but they deliver superior performance, greater precision, and reduced labor costs.

Financing and Leasing Options

- Direct Purchase: Paying upfront can be a viable option if you have the available capital. This method usually offers the best ROI over the machine’s lifespan.

- Leasing Options: Leasing a beam saw machine can reduce your initial financial burden and allow you to upgrade as your production needs evolve.

- Business Loans and Grants: Explore financing options specifically tailored to equipment purchases. Many financial institutions offer loans with competitive rates, and there may be government grants or tax incentives available for investing in energy-efficient or industrial machinery.

Return on Investment (ROI) Analysis

When calculating ROI, consider the following:

- Increased Productivity: A quality beam saw machine can significantly reduce cutting time, which in turn increases overall throughput.

- Reduced Material Waste: Precision cutting minimizes waste, leading to better material utilization and lower costs per unit produced.

- Lower Labor Costs: Automation and precision reduce the need for manual intervention, thereby decreasing labor costs and increasing profitability.

- Maintenance and Downtime: Investing in a reliable machine can minimize unplanned downtime and reduce maintenance expenses over the machine’s lifecycle.

Perform a detailed cost-benefit analysis that factors in these elements to determine the most cost-effective solution for your business.

8. Maintenance and Safety Tips

Proper maintenance and safe operation are essential for maximizing the lifespan of your beam saw machine and preventing accidents. Here are detailed tips:

8.1. Maintenance Tips

- Regular Cleaning: Keep the machine clean to prevent dust buildup, which can affect performance and safety. For example, Blue Elephant CNC recommends cleaning dust and residue from inside and above the machine every shift (Beam Saw Machine: The Best Saw For Cutting Panels).

- Lubrication: Follow the manufacturer’s recommendations for lubricating moving parts to ensure smooth operation, reducing wear and tear.

- Blade Inspection: Regularly check and replace saw blades as needed to maintain cutting quality and safety, as highlighted in maintenance sections of various manufacturer guides.

- Electrical Checks: Periodically inspect electrical components for signs of wear or damage to prevent malfunctions, ensuring the machine operates safely.

8.2. Safety Tips

- Training: Ensure all operators are properly trained in the safe use of the machine, understanding controls and emergency procedures.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, hearing protection, and gloves, to protect against hazards.

- Lockout/Tagout: Implement procedures to safely shut down the machine during maintenance or when not in use, preventing accidental startups.

- Emergency Preparedness: Have clear emergency procedures in place and ensure all staff know how to respond to accidents, enhancing workplace safety.

These practices not only extend the machine’s life but also create a safer working environment, reducing the risk of injuries and downtime.

9. Conclusion

Choosing the right beam saw machine is a significant investment that can greatly impact your woodworking operation’s efficiency and profitability.

By understanding the different types, key features, and how to select the best machine for your needs, you can make an informed decision that aligns with your production goals and budget.

At our woodworking machine website, we are committed to providing you with the best selection of beam saw machines and exceptional customer service.

Our experts are here to answer any questions you have and help you find the perfect machine for your workshop.

Don’t hesitate to contact us today to learn more or to schedule a demonstration, and take the first step toward enhancing your production capabilities with a top-quality beam saw machine.