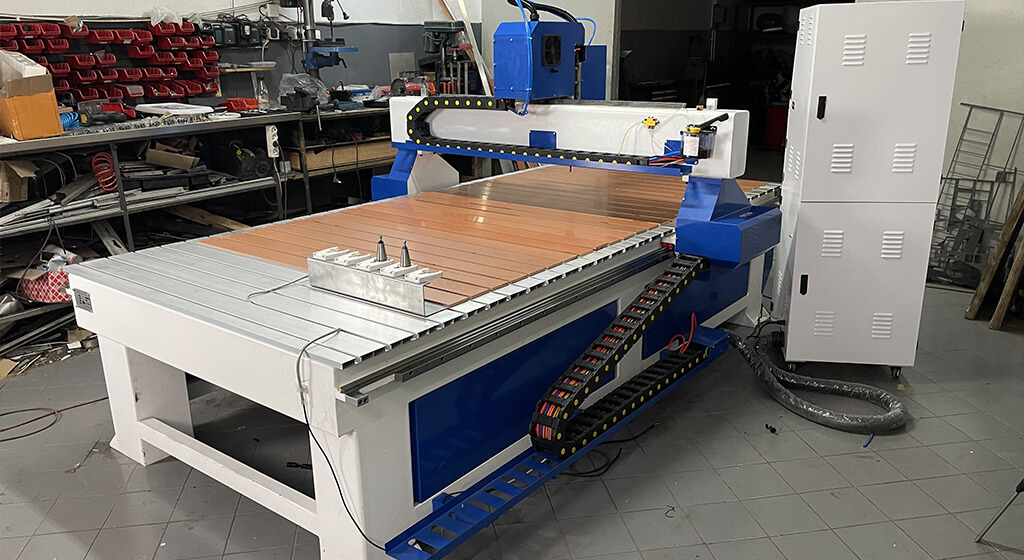

CNC Routers are precision tools, pivotal in woodworking and manufacturing.

Like any complex machine, their optimal performance hinges on regular maintenance.

Proper care not only ensures seamless operations but also extends the machine’s lifespan, safeguarding your investment.

Table of Contents

1. Understanding the Basics of CNC Router Maintenance

Maintaining a CNC router starts with understanding its needs.

Components like spindles, guide rails, and software require regular checks.

A structured approach, segmented into daily, weekly, and monthly routines, simplifies this task and ensures consistency.

2. The Ideal Environment for CNC Routers

The environment significantly impacts a CNC router’s performance:

- Temperature and Humidity Control: Fluctuations can compromise precision. Maintain a stable, controlled environment to avoid material distortions and electronic malfunctions.

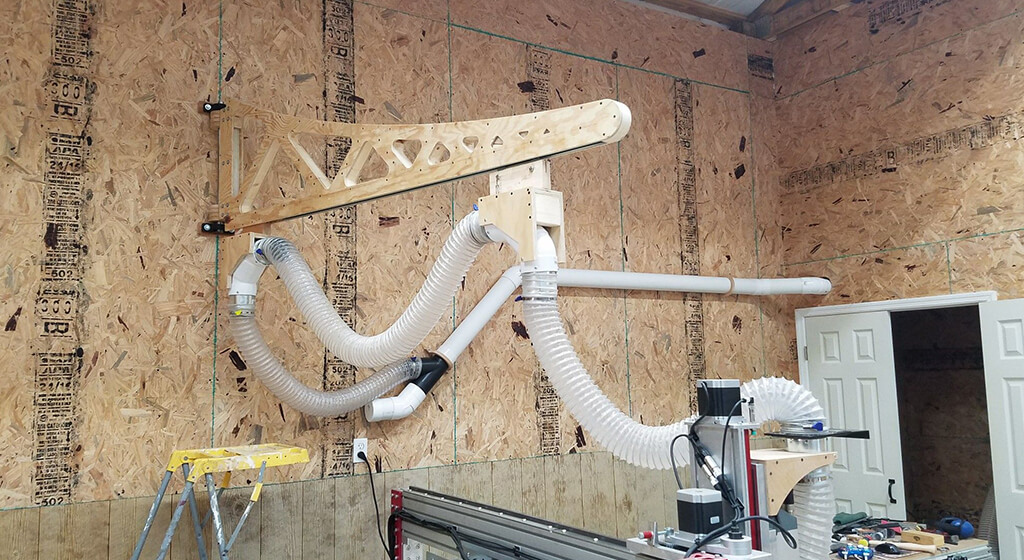

- Positioning: Ensure adequate airflow and easy access for maintenance.

- Cleanliness: Dust and debris are the silent adversaries of CNC routers. Employ dust collection systems and clean workspaces diligently.

3. Daily Maintenance Tasks

- Cleaning: Begin each day with a thorough cleaning. Use compressed air or specialized vacuums to clear debris, paying attention to guide rails and spindles.

- Basic Inspections: Spot-check for loose bolts, frayed wires, and unusual noises. Early detection prevents escalation.

- Ensuring Smooth Operation: Monitor moving parts for fluid motion, and address resistance or unusual vibrations promptly.

4. Weekly Maintenance Tasks

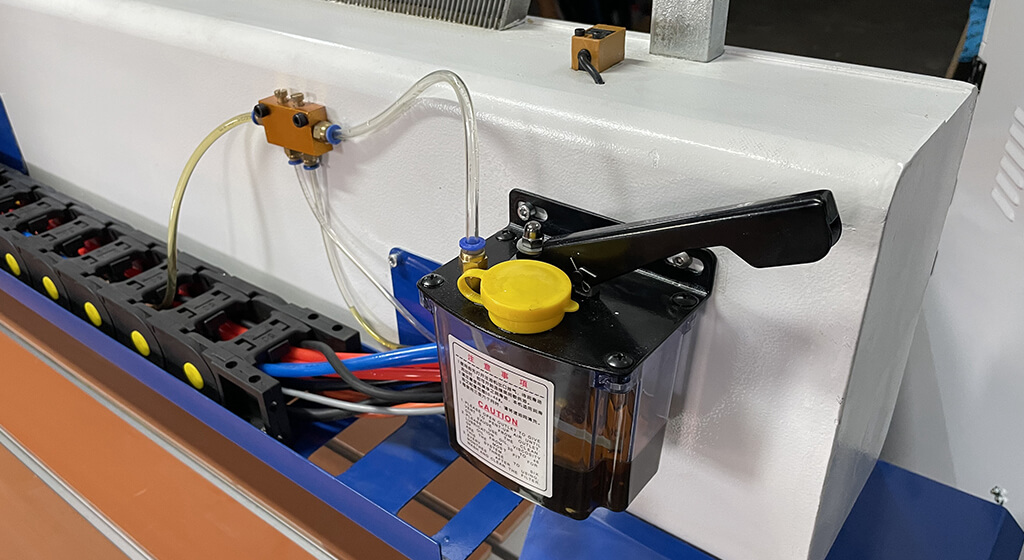

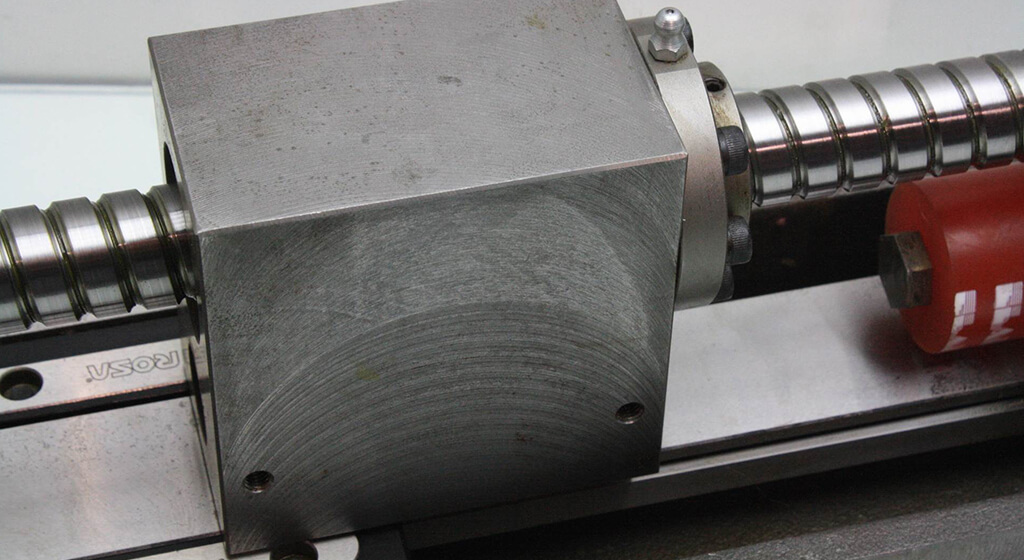

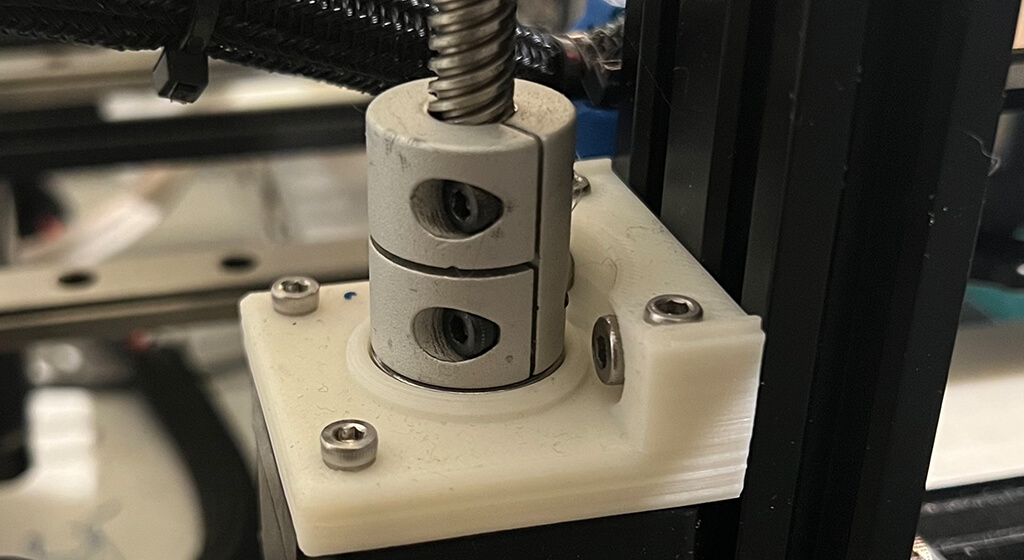

- Lubrication: Friction is the enemy of precision. Apply manufacturer-recommended lubricants to ball screws and linear guides to ensure seamless motion.

- Detailed Inspections: Examine mechanical systems for wear and fatigue. Review electrical connections for stability.

- Software and Firmware: Regularly update to the latest versions to enhance functionality and address vulnerabilities.

5. Monthly Maintenance Tasks

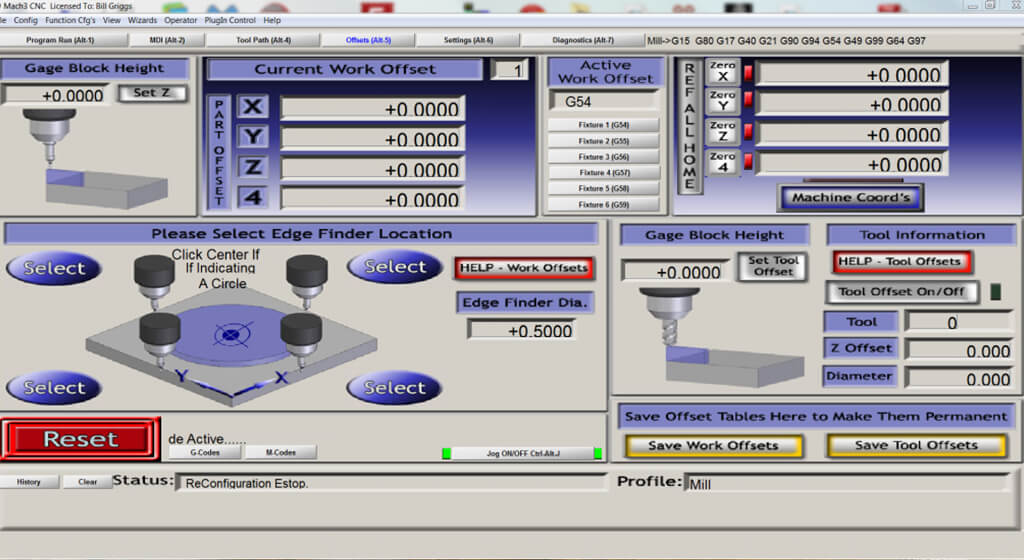

- Diagnostics: Use diagnostic software to analyze machine health. Identify and resolve errors before they impact operations.

- Calibration and Alignment: Maintain precision by recalibrating axes and aligning tools to specifications.

- Spare Parts Inventory: Audit spare parts stock, ensuring availability of critical components.

6. Essential Spare Parts and Their Maintenance

6.1. Regular Cleaning

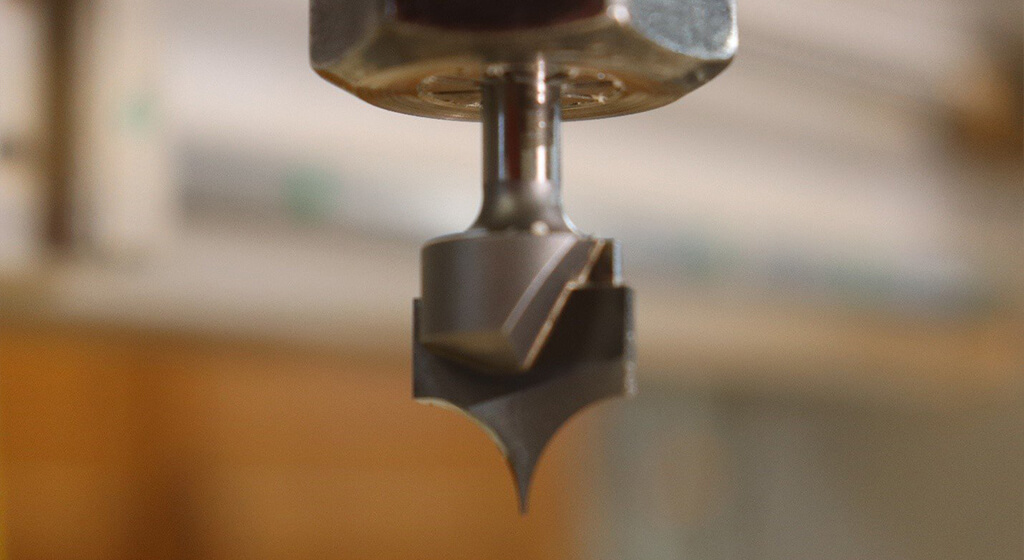

Router bits are the cutting tools that shape your materials. Regularly inspect for wear and replace them promptly to maintain cutting precision.

Store them in a dry, organized space to avoid corrosion.

6.2. Collet and Tool Holders

Critical for holding bits securely, collets and tool holders must be cleaned and checked for deformation regularly.

Damaged holders can lead to operational inefficiencies and safety risks.

6.3. Spindle Motors

6.4. Linear Guides and Ball Screws

6.5. Automatic Tool Changer Tool Forks

6.6. Vacuum Suction Pods

6.7. Filters and Way Wipers

6.8. Stepper Motors and Bearings

7. Spare Parts Management

Having key parts on hand minimizes downtime:

- Router Bits: Essential for cutting precision.

- Spindle Motors: Critical for tool rotation.

- Drive Belts and Bearings: Ensure smooth motion and power transmission.

- Filters: Keep lubrication and cooling systems contaminant-free.

8. Professional Support and Operator Training

- Manufacturer Support: Schedule professional maintenance visits for comprehensive care.

- Operator Training: Educate operators on machine handling and troubleshooting. Knowledgeable operators are your first line of defense against misuse and wear.

9. Advanced Maintenance Strategies

- Predictive Maintenance: Leverage sensors to monitor performance metrics in real-time, identifying issues before failure.

- Proactive Approaches: Regularly review operational data to refine maintenance schedules and enhance efficiency.

10. Prolonging Machine Lifespan

Avoiding common pitfalls, such as neglecting lubrication or ignoring environmental factors, significantly extends the machine’s life.

A well-maintained CNC router delivers precise, high-quality outputs consistently.

11. Conclusion

The path to CNC router longevity lies in regular maintenance, attention to environmental conditions, and professional support.

By investing time and resources in proactive care, you not only enhance the machine’s performance but also secure a robust return on investment.

Maintenance isn’t just a necessity—it’s a commitment to excellence.