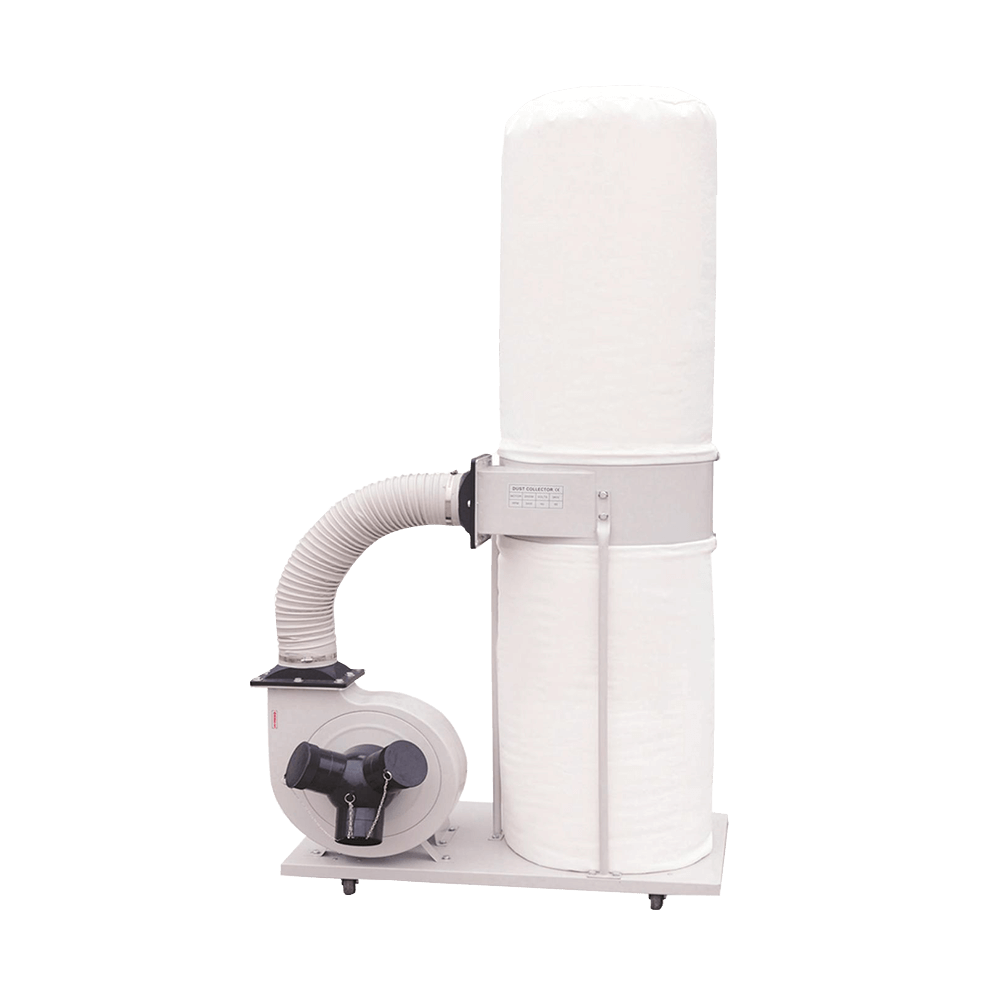

Dust Collector

Dust Collector.

At BESTIN, we understand the importance of maintaining a clean, safe, and efficient environment for woodworking. Our expertly engineered wood dust collector systems are tailored to meet the diverse needs of workshops and manufacturing facilities, ensuring optimal performance while protecting worker health and equipment.

Benefits

Whether you’re setting up a new production line or upgrading your dust collection system, BESTIN offers the most effective solutions for you.

Benefits from Wood Dust Collection:

- Cyclone Dust Collection Technology: Maximizes dust separation efficiency.

- Portable and Stationary Options: Meet diverse operational needs.

- High-Capacity Dust Bags: Minimize frequent emptying.

- Advanced Filtration Systems: Capture fine particles for cleaner air.

- Seamless Integration: Easily connect to existing machinery.

Applications of Wood Dust Collector

Panel Saw Cutting

Efficiently capture fine sawdust generated during precision saw cutting operations.

- Enhanced visibility for accurate cuts.

- Minimized machine wear and tear.

- Improved air quality for operator safety.

Edge Banding

Keep work areas clean while ensuring seamless edge banding machine application.

- Dust-free surfaces for better glue adhesion.

- Reduced downtime for maintenance.

- Extended machine life.

CNC Routers

Handle high-volume dust and debris created during CNC Router operations.

- Maintain precision routing.

- Improve part quality and consistency.

- Prevent build-up in critical machine components.

Wood Sanding

Capture fine sanding dust to maintain a clean environment when running sanding machine.

- Enhanced safety and air quality

- Consistent finish quality on workpieces

- Reduced health risks for operators

Our Service

At BESTIN, we don’t just offer dust collector machine; we offer comprehensive after-service, spare parts, and shipping support to ensure your machines stay in optimal working condition:

Spare Parts

Affordable Solutions

FAQ About Industrial Dust Collector

What Is A Wood Dust Collector?

A wood dust collector is a machine designed to capture wood dust, chips, and other debris produced during woodworking processes such as cutting, sanding, and milling.

It helps maintain a clean and safe work environment by preventing the accumulation of hazardous dust and ensuring the proper functioning of woodworking equipment.

Why Do I Need A Wood Dust Collector In My Woodworking Shop?

A wood dust collector is essential for improving air quality, enhancing safety, and maintaining equipment efficiency. Wood dust can cause respiratory issues, fire hazards, and equipment damage.

A dust collector helps reduce these risks by capturing harmful particles before they spread throughout the shop.

How Does A Wood Dust Collector Work?

Wood dust collectors work by using a vacuum system that pulls dust and debris from the woodworking machine via ductwork.

The collected particles are then filtered and stored in a dust bag or container.

The cleaner air is returned to the environment, reducing airborne dust and maintaining a safe workspace.

What Types Of Wood Dust Collectors Are Available?

There are several types of wood dust collectors, including:

- Cyclone Dust Collectors: Use centrifugal force to separate dust from air.

- Baghouse Dust Collectors: Use fabric filters to capture dust particles.

- Portable Wood Dust Collectors: Mobile units that can be moved around the shop.

- Centralized Dust Collection Systems: Large systems designed to handle multiple machines.

What Size Wood Dust Collector Do I Need?

The size of the dust collector you need depends on the size of your workshop, the number of machines in use, and the volume of dust generated.

Larger woodworking operations will need more powerful, centralized systems, while smaller shops may benefit from portable or single-machine dust collectors.

Can A Wood Dust Collector Be Used With Multiple Machines?

Yes, many wood dust collectors can be configured to handle dust from multiple machines.

Centralized systems with ductwork and multiple inlets allow you to connect several machines to one dust collection unit, making them ideal for large-scale operations.

What Maintenance Does A Wood Dust Collector Require?

Regular maintenance is necessary to ensure optimal performance:

- Cleaning or replacing filters.

- Emptying the dust collection bags or containers.

- Inspecting hoses, ductwork, and motors for wear or damage.

- Checking for proper airflow and suction power. Routine maintenance helps prevent blockages, ensures efficiency, and extends the lifespan of the system.

How Do I Install A Wood Dust Collector?

Installation varies depending on the type and size of the dust collector.

Portable units are typically plug-and-play, requiring minimal setup. For centralized systems, installation may require professional assistance for proper ductwork design, mounting, and connection to multiple machines.

How Do I Choose The Best Wood Dust Collector For My Workshop?

When choosing a wood dust collector, consider factors like:

- Airflow capacity (CFM): Ensure it matches the needs of your shop.

- Type of dust produced: Different collectors handle various types of dust.

- Size and mobility: Determine whether a stationary or portable unit fits your needs.

- Filtration efficiency: High-efficiency filters capture smaller particles for better air quality.

Can A Wood Dust Collector Be Used For Other Materials?

Some wood dust collectors can handle materials like plastic or metal dust, but it’s essential to ensure the collector is rated for those materials.

Wood dust collectors are specifically designed for wood and woodworking debris, so using them for other types of dust without proper adjustments could lead to inefficiency or even damage to the system.

Are Wood Dust Collectors Noisy?

Dust collectors can produce noise due to the motor and airflow.

However, there are models with noise-reducing features such as insulated housing or quieter motors.

Choosing a model with lower decibels can help reduce the overall noise level in your workshop.

What Is The Price Of A Wood Dust Collector?

The price of a wood dust collector depends on its type, size, and features.

Portable units are generally more affordable, while centralized systems and cyclone dust collectors are more expensive due to their larger capacity and complex installation requirements.

Contact us for a quote based on your specific needs.

Can I Make My Own Wood Dust Collector?

DIY wood dust collectors are possible, and there are various plans available for home-built systems.

However, a professionally manufactured dust collector is typically more efficient, safer, and durable, offering higher performance and reliable filtration.

How Often Should I Replace The Filters In A Wood Dust Collector?

The frequency of filter replacement depends on the usage and the type of material being collected.

Generally, filters should be replaced or cleaned every 6-12 months, or sooner if you notice a drop in airflow or suction power.

Can A Wood Dust Collector Improve The Lifespan Of My Woodworking Machines?

Yes, by removing dust and debris from the workspace, a dust collector prevents buildup on your woodworking machines, which can cause wear and tear.

Clean machinery operates more efficiently and lasts longer, reducing maintenance costs and downtime.