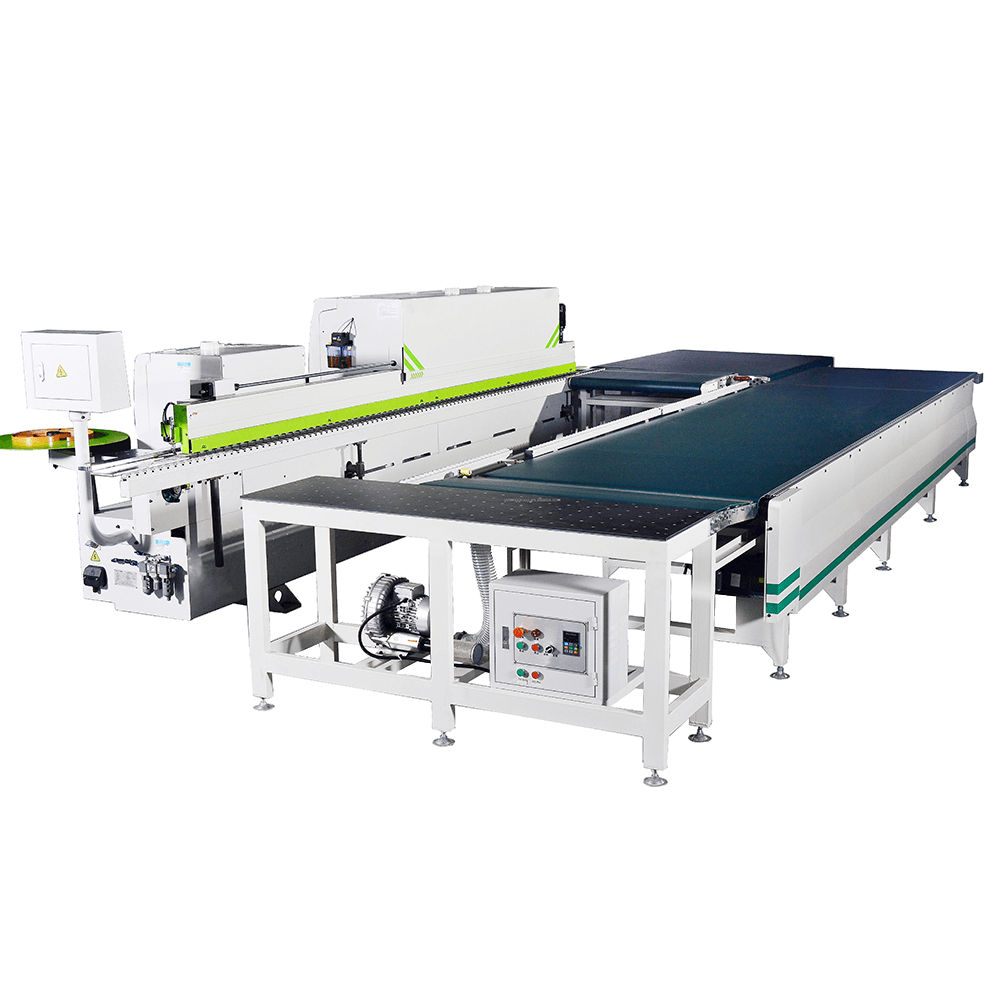

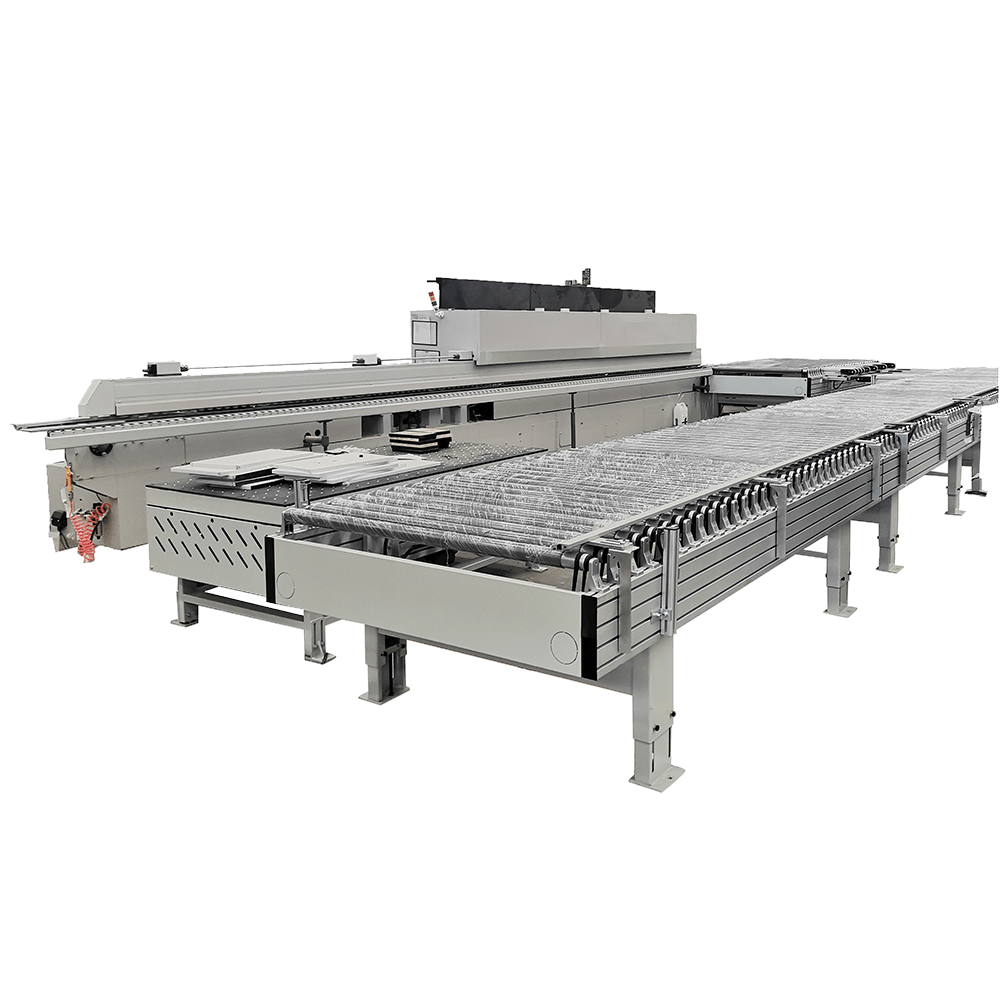

Edgebander Return Conveyor

Edgebander Return Conveyor.

Our edgebander return conveyor serves as an invaluable complement to single-sided edge banding machines, seamlessly integrating with their functionalities. By automating and organizing the material flow, this conveyor significantly boosts the efficiency of the edge banding machine, resulting in a more productive and cost-effective operation.

Benefits

Our advanced return conveyors offer seamless integration with your edge banding machines, helping to maintain smooth workflows by automatically returning finished workpieces to the operator.

Benefits

- Optimized Workflow: Reduce labor requirements and increase efficiency by automating material handling.

- Customizable Options: Tailored configurations available to meet specific factory needs.

Manufacturing Excellence

Our return conveyors are part of BESTIN’s commitment to providing high-quality industrial woodworking machines and accessories.

We combine superior engineering, advanced automation, and customer-driven design to meet the unique needs of furniture manufacturers worldwide.

Spare Parts Availability

Affordable Solutions

Maximize your production efficiency with BESTIN’s advanced Edge Banding Machine Return Conveyor solutions.

Contact our expert team today to find the right system for your factory.

FAQ About Edgebander Conveyor

What is an Edge Banding Machine Return Conveyor?

An Edge Banding Machine Return Conveyor is an automated system designed to transport finished panels or workpieces back to the operator after they have passed through the edge banding machine.

This system eliminates the need for manual handling, improving efficiency and reducing labor costs on the production floor.

How does an Edge Banding Machine Return Conveyor work?

The return conveyor is integrated with the edge banding machine to receive the workpieces once they are completed with the edge banding process.

The conveyor moves the panels smoothly and automatically, allowing operators to focus on other tasks, such as quality control or preparation for the next phase of production.

Can I customize the Edge Banding Machine Return Conveyor to fit my factory layout?

Yes, our Edge Banding Machine Return Conveyors are customizable to fit different factory layouts.

We offer adjustable conveyor lengths, speeds, and heights to match your specific needs and optimize material flow in your production environment.

What materials can the Return Conveyor handle?

The return conveyor is designed to handle various types of wooden panels, MDF, plywood, particleboard, and more.

It can be configured to manage different panel sizes, weights, and thicknesses, making it versatile for a wide range of woodworking applications.

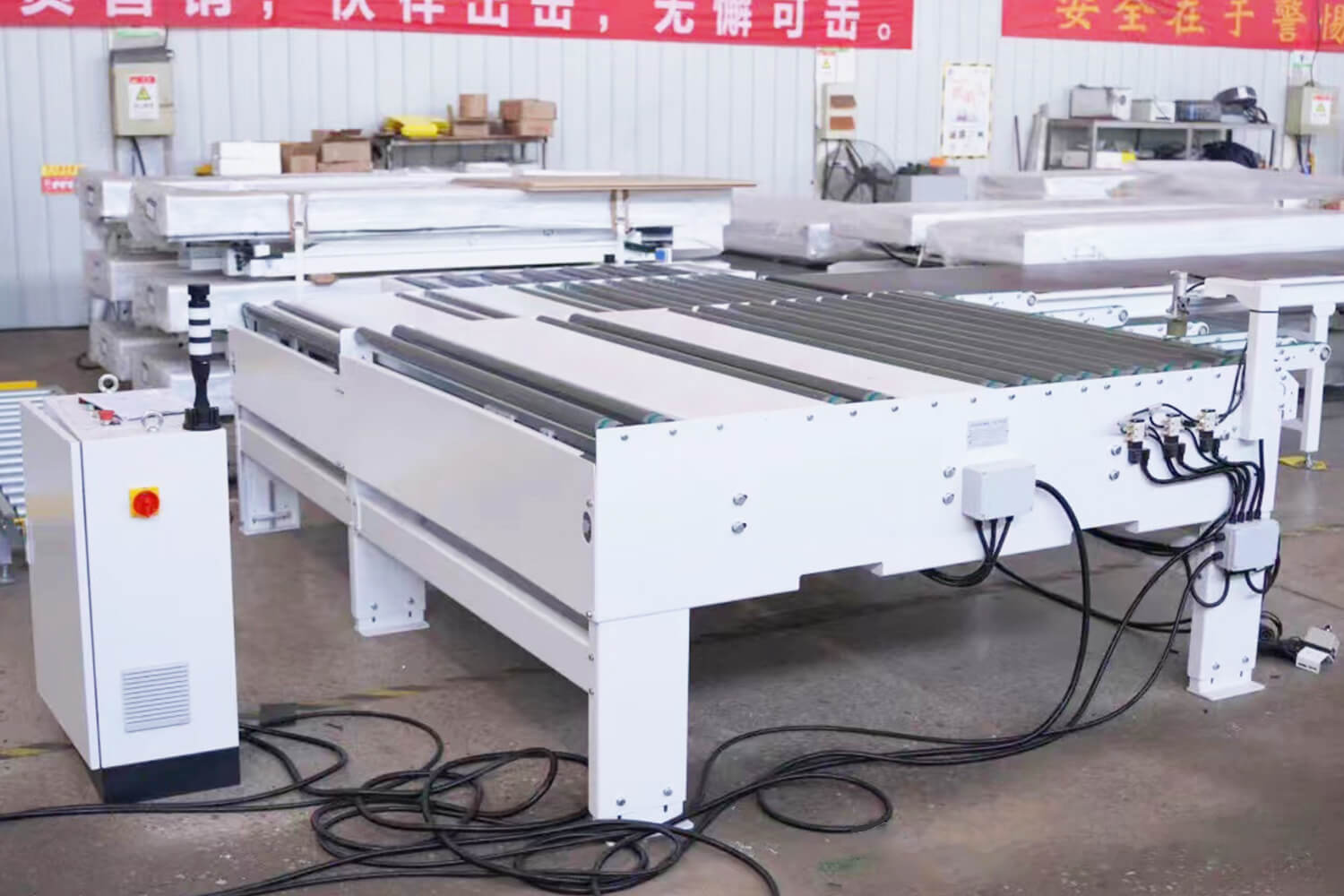

Is it difficult to install the Edge Banding Machine Return Conveyor?

No, our return conveyors are designed for easy integration with existing edge banding machines.

Installation is typically straightforward, and our team can assist with setup and alignment to ensure seamless operation.

What is the maintenance requirement for the Edge Banding Machine Return Conveyor?

Maintenance for the return conveyor includes regular cleaning, inspection of moving parts, and lubrication to ensure smooth operation.

We recommend periodic checks to keep the system in optimal working condition. Additionally, we offer maintenance services to support ongoing needs.

Can I purchase replacement parts for the Edge Banding Machine Return Conveyor?

Yes, we provide a full range of return conveyor parts to ensure your system continues to perform at its best.

Whether you need belts, motors, or other components, we offer quick and reliable access to all necessary parts.

What is the price of an Edge Banding Machine Return Conveyor?

How can I integrate the Edge Banding Machine Return Conveyor with other machinery in my production line?

Our return conveyors are designed for compatibility with a variety of edge banding machines and other industrial woodworking machines.

Our team can work with you to ensure that the conveyor integrates seamlessly with your existing production line for maximum efficiency.

Do you offer international shipping for the Edge Banding Machine Return Conveyor?

Yes, we offer global shipping options for our Edge Banding Machine Return Conveyors.

We ensure fast, safe, and reliable delivery to large and medium-sized furniture factories worldwide.

How long does the Edge Banding Machine Return Conveyor last?

With proper maintenance, our edge banding machine return conveyors are built to last for many years, even in high-demand production environments.

The durable construction and industrial-grade components ensure long-term performance.

What is the lead time for delivery of the Edge Banding Machine Return Conveyor?

Do you offer after-sales service for the Edge Banding Machine Return Conveyor?

Can Your Edge Banding Machine Return Conveyor Work With Other Edge Banding Machine?

Yes, our Edge Banding Machine Return Conveyor is designed to be highly adaptable and can work with most edge banding machines from various manufacturers, such as KDT, SCM, HOLZHER, HOMAG, BIESSE, IMA SCHELLING.